Free Backyard Garden

Shed Materials List

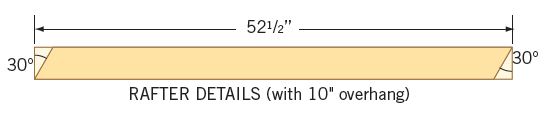

14 rafters, 1 1/2

x 3 1/2” x 521⁄2”

12 rafter supports, 1 1/2” x 2 1/2” x 8 1/2”

8 rafter blocking boards, 1 1/2” x 5 1/2” x 22

1/2”*

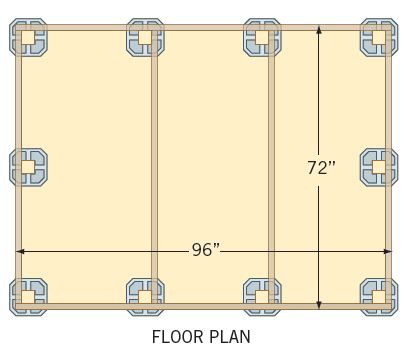

10 deck blocks, precast concrete, for 4-by-4

posts

As needed floor posts, 3 1/2” x 3 1/2” x 12”*

As needed floor frame spacers, 1 1/2” x 3 1/2” x

length*

2 long floor edge boards, pressure-treated, 1

1/2” x 5 1/2” x 96”

4 floor joists, pressure-treated, 1 1/2” x 5

1/2” x 69”

11⁄2 sheets pressure-treated floor decking, 5/8”

x 48” x 96”

18 wall studs, 1 1/2” x 3 1/2” x 92 1/2”

6 long bottom/top plates, 1 1/2” x 3 1/2” x

96”**

6 short bottom/top plates, 1 1/2” x 3 1/2” x

65”**

1 door lintel, 3 1/2” x width as needed x length

as needed

2 window studs, 1 1/2” x 3 1/2” x length as

needed

2 top/bottom window frames, 1 1/2” x 3 1/2” x

length as needed

6 or 7 sheets*** wall sheathing (plywood or OSB),

7/16” to 1/2” x 48” x 96”

4 1/2sheets roof sheathing (plywood or OSB),

7/16” to 1/2” x 48” x 96”

Metal rafter hardware

Note:

All materials should be construction-grade lumber

unless otherwise noted. Dimensions are actual — for

example, 1 1/2 inches x 3 1/2 inches are the actual

dimensions of a 2-by-4. Go to your local

Lowe's, back up the truck and go!

*Cut to

length as needed

**Cut upper top plates to overlap corners

***Depending on the size of door and window you

select

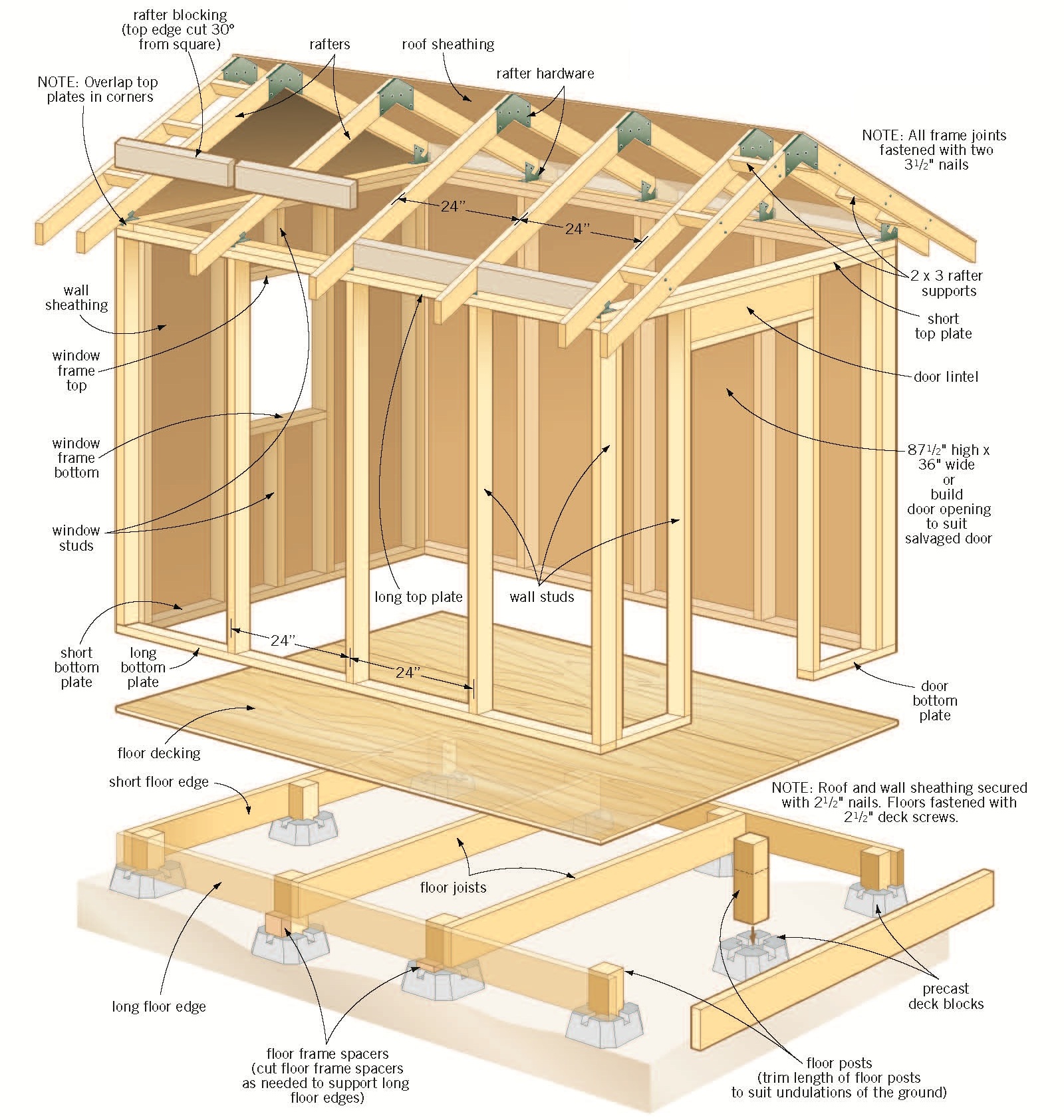

Build the Shed Floor

The best spot for a

shed is level, well-drained ground close to where

you work in your garden or backyard. The location

doesn’t need to be perfectly flat, nothing is

perfect; the foundation design shown in the shed

plans allows for adjustments to make the floor

level. Small sheds require only a top-of-soil

foundation, even in locations with freezing winter

temperatures. Precast concrete deck blocks

work perfectly for this. Don't assume you need

or don't need a foundation for your shed, though.

When in doubt, consult a pro.

To eliminate the need

for any kind of floor beams for your shed, you’ll

need a deck block at each corner, with two more

blocks equally spaced along the 8-foot sides and one

in the center of each 6-foot side. If you expect to

store particularly heavy items inside your garden

shed, consider installing three deck blocks between

each corner on the 8-foot walls, instead of two.

Deck blocks include a

central pocket sized to fit the standard 4-by-4

vertical posts that typically hold up a deck. In the

case of these shed plans, pressure-treated 4-by-4s

function in a similar way, but in short lengths —

just enough to compensate for any variation in the

shape of the ground (see the plans).

Start by setting deck

blocks on the ground, positioned as shown in the

shed plans diagrams below. While the area doesn’t

have to be perfectly level, you should make the

ground roughly level where each block will rest.

Temporarily place some straight 2-by-6 lumber on

edge in the top grooves of the blocks to orient the

blocks in a straight line. Arrange two rows of four

blocks parallel to each other to form both long

walls, then measure diagonally across the outside

corners to determine how square the arrangement is.

If the two long walls are parallel, and diagonal

measurements taken across corners are equal, then

each corner is guaranteed to be 90 degrees. Finish

up by placing one deck block in the middle of each

6-foot wall after you have aligned and squared the

8-foot walls.

Remove the 2-by-6

lumber guides, then put a 12-inch length of 4-by-4

lumber into each deck block, positioned vertically

in the central recess. These 4-by-4s will be

slightly too long right now, but that’s exactly what

you want.

The 2-by-6s that

form the outer perimeter of the floor frame rest

on the outside top edge of the deck blocks,

tight to the outer faces of the 4-by-4 posts.

Use a 4-foot level and an 8-foot 2-by-6 to

determine the highest deck block in the group,

then use this as your starting point for

installing the floor frame of the shed. Use a

single galvanized 3 1⁄2-inch deck screw to lock

the 2-by-6 to the 4-by-4 on the highest deck

block, then raise the other end of the 2-by-6 so

it’s level before locking the other end of the

2-by-6 to its 4-by-4. The 2-by-6 won’t rest on

all the blocks, but should rest on at least one.

Continue working all around the floor frame of

the shed in this manner until all perimeter

2-by-6s are in the same level plane. Trim all

excess 4-by-4s flush with the top of the 2-by-6s

using a chain saw or reciprocating saw, then add

2-by-6 floor joists running between the two

8-foot walls. Make sure each joist fits tightly

within the outer edges of the floor frame, and

then fasten the joists to the side of the

4-by-4s with screws.

Complete the floor

frame of the shed by driving three 3 1⁄2-inch

deck screws per joint, then custom-cut spacers

out of 1 1⁄2-inch-thick construction lumber to

fill the gap between the underside of the

2-by-6s and the top of the deck blocks. You

can’t rely on screws alone to hold up the floor

frame in the long term. Finish up by installing

a pressure-treated, five-eighths-inch-thick

plywood sub floor on top of the floor frame,

secured with 2 1⁄2-inch deck screws driven every

6 to 8 inches.

Frame the Shed

Walls

This shed’s walls

are built in the same way that the walls of most

full-size homes are built. The plans show how

2-by-4 top plates and bottom plates extend

horizontally around the perimeter of the

building, with vertical studs defining wall

surfaces. Notice that the two short walls fit

inside the two longer ones, fastened together at

the corners with 3 1⁄2-inch deck screws and

overlapping top plates. Framing is the

most important part of building a quality shed

that lasts for years, so you want to make sure

you do this right if you want your shed to last.

To build the

framing for each wall, begin by temporarily

screwing a 2-by-4 top plate and 2-by-4 bottom

plate together face to face, then set this pair

on its edge on the plywood floor. Next, mark the

position of the wall studs on the edges of both

of these 2-by-4s, spacing the center of each

stud 24 inches apart. The shed plans show

detailed layouts for all walls and how to frame

door and window openings. The shed plans don’t

offer measurements for these openings though,

because this shed is perfect for using scrounged

windows and doors, and these can be of any size.

You can hinge doors directly onto the rough

frame of the shed, but attaching windows will

work a little differently.

A salvaged wooden

sash can be fixed permanently into the shed

frame, but beware: Fixed windows such as these

attract and trap flies, making a buzzing, dirty

mess. I suggest using another type of window. If

you do, you’ll need to create a rough window

frame opening large enough to accommodate the

entire window unit, with an extra half-inch

clearance on the sides, top and bottom for

adjustment.

Separate the

2-by-4 plates, space them about 8 feet apart

on the floor, and nail 92 1⁄2-inch-long

studs between them.

Immediately after you’ve built one long

wall, get some help to tilt it upright,

then use 4-inch deck screws to fasten

the bottom wall plate to the floor,

positioning the screws so they sink into

the edge of the 2-by-6 floor frame.

Assemble and raise the other walls,

adjust them so they’re plumb in the

corners and fasten them with deck

screws. Add a second layer of wall

plates on top of the first, overlapping

across the corners. Complete the walls

by covering the frame with sheathing.

Exterior-grade plywood siding is an

easy, inexpensive choice. It includes

vertical grooves for decoration and

accepts any kind of paint or stain.

Regardless of what you use, don’t

wrestle with the complication of cutting

window openings before adding sheathing.

Instead, apply sheathing to the walls

from the outside, covering them

completely, then cut the window and door

openings afterward, following the framed

openings from inside using a chain saw

or reciprocating saw.

Build

the Shed Roof

While the

walls and framing are the most important

part of your shed, the roofing is the

hardest. Most people have to

consult with a professional shed builder

to get this done right, but with a

little time and effort, the average

person should be able to build a quality

shed roof. The simplest way to

make a roof frame for a small shed is to

use steel connector plates made

especially for the job. Using this

hardware eliminates the need for fancy

cuts on the rafters and will create a

strong shed roof. Cut the 2-by-4 rafters

at 30-degree angles (see the plans),

then bring them together on top of the

building using steel plates (peak

brackets) and screws.

With the

rafters in place, cut two triangular

pieces of wall sheathing to close in

the gable ends, fastening them both

to the top of the wall and the faces

of the outermost rafters with nails.

Notice

how the roof frame sits on top of

the walls and that there are spaces

between the rafters. If you leave

these open, birds, bugs and rodents

will get into your shed. The best

time to fill spaces between rafters

is now, before the roof sheathing

goes on. Cut 2-by-6 blocking to fit

within each space. If you have

access to a table saw, use it to

angle the top sides of the blocks to

match the roof slope. Fasten the

blocks to the top plate with screws.

Even

a small shed looks best with a roof

overhang on the triangular front and

back ends of the building. So,

before you cover the roof with

half-inch plywood, extend the roof

frame by attaching three rafter

supports to each end rafter with

screws, then fasten the overhanging

rafters to those supports.

It’s

much easier to safely handle

rafters, roof sheathing and shingles

when you’re standing firmly on a

scaffold than when you’re balancing

on a ladder. Set up the scaffolding

inside the shed for roof

construction, then move it out next

to the eaves as a shingling

platform.

DIY

sheds offer great value, great

durability, and the opportunity

to exercise your creativity.

Build one yourself, and you’ll

wonder why anyone would ever do

it differently. We hope

you have enjoyed this free shed

plan and come back for more!

Free

Backyard Garden Shed Storage Plans

(Right Click on Image, and Select View as Image or

Save As to See the FULL SIZE Picture)

|