Project Introduction

Everyone enjoys the look and feel of fine wood furniture. It

has a warmth and elegance that enhances every home. With the

prices of quality wood furniture increasing, many do it

yourselfers are making their own custom pieces. In this

pamphlet, we are going to demonstrate the correct way to

build a beautiful end table in your own workshop. We will

take you through step by step, from initial planning to the

finished product. As you build this project, remember, every

new skill and technique you

learn building this table can be carried over into other

woodworking projects.

Planning

Review this article thoroughly

before proceeding with this project. Go through the tools

and materials check-list and study your

plan carefully. Know the safety standards for the project.

Plan ahead and gather the items that you will be using, and

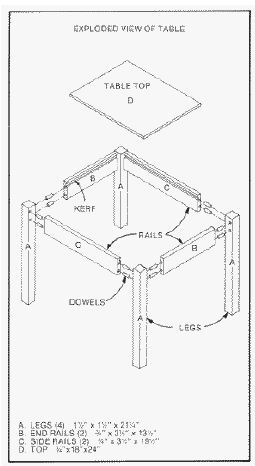

place them where you will build the table. The plans shown

here are for a basic table. You may want to adapt them to a

design of your choice. Before you begin your project, you

will want to become familiar with the wood working terms

shown below.

Terminology

Miter

Cut - Angle cut across the width or thickness of the board

Rabbet - L-shaped cut

Dado - Channel cut across the board, into which a second

piece of wood is fitted

Kerf - Width of the blade

Countersink - To set a screw head at or below the surface

Dowel - Wooden pin used to provide strength and alignment

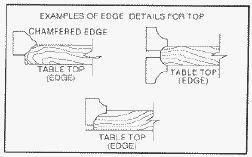

Chamfer - Corner of a board beveled at a 45 degree angle

Crosscut - Cut across the grain

Ripcut - Cut with the grain

Wood Selection

Before you purchase your wood and select a finish for your

end table, you should ask yourself some simple questions

about how you plan to use and display it in your home. Where

will the end table be located? Do the dimensions of the end

table fit

properly in the space you have allowed for it? Is it a high

traffic area? Will people be placing wet glasses, or

propping their feet on it?

The two basic categories of wood are hardwood and softwood.

Hardwood is more durable and less prone to dents and

scratches. It is also more expensive but will finish to a

better advantage. Soft woods, like pine, are more prone to

dents and scratches and do not have the durability of

hardwood. Softwoods are much less expensive and easier to

find. Ask your lumber supplier to show you "Class 1 " or

"Select Grade" lumber. Make sure it is properly dried,

straight, and free of knots and defects. (It may be

impossible to be completely free of defects but be sure you

understand how to cut around these.)

Wood selection for your end table should be of a durable

hardwood. In our plan, the choice was oak. Solid pieces used

for the table top will expand and contract with changes in

humidity. So that this will not create a problem, be sure

all your stock is of

a similar moisture content. To allow for seasonal changes,

do not glue the top to the rails. Many people use veneered

wood to avoid this seasonal problem.

Usually it is best to purchase surfaced stock that is smooth

and of a uniform thickness. However, you can use a planer

and purchase the less expensive rough stock and finish it at

home. Any areas of the wood that show cupping or crowning

will need to be planed by using a jointer or table saw.

Now that you have reviewed the safety hints, learned the

mistakes to avoid, reviewed the basic components and

gathered your tools and materials for your end table - you

are ready to BEGIN!

A Step By Step Approach

Don't let the job of building this end table make you

apprehensive about beginning. This wood plan makes

building an end table easy by dividing the project into six

simple, manageable steps. Each step is then broken down into

a series of instructions. You will find each step and the

instructions for completing them NUMBERED to help you

remember exactly what stage of the project you are doing.

Refer to the diagrams if you have questions.

The

steps to follow in making this lovely end table are:

1. Preparing the Stock

2. Preparing the legs and Rails

3. Assembling the top

4. Assembling the frame

5. Attaching the top

6. Finishing the assembled table

Preparing the Stock

If you did not buy pre-planed stock, start with step 1 of

step 1; if you did buy preplaned stock, start with step 2 of

step 1.

1. Make the stock smooth and uniform. To do this use a

planer. Plane the stock to a uniform 3/4" thickness.

2. Mark the stock for cutting. Measure carefully and make

your marks clearly. Note: Stay away from a circular saw to

make your cuts because it is very hard to get a straight

cut. Instead use a table saw, radial arm saw, or similar

multipurpose tool. Set your guides and use a push stick,

fence straddler, or a push block to keep your hands away

from the blade.

3. Rip (cut with the grain) the stock to the proper width.

Measure carefully and extend mark with steel square to

provide a guide for table saw. Cut to the waste side of the

wood for proper cutting. Set the fence carefully before

ripping. When ripping you must be sure that at least one

side of the stock is perfectly straight so the stock can be

ripped straight. Use a jointer, or a straight piece of

plywood and a table saw to get this straight edge.

4. Crosscut (cut against the grain) the stock to its proper

length. Measure and mark the stock carefully. Be sure to cut

the stock 1" 2" longer. The stock will be cut to final

length after the top is built.

Preparing the Legs and Rail

Choosing a style for the legs of your end table allows you a

great deal of creativity. We have selected the mission

style leg which features a taper that is heavier at the top

than at the bottom.

• Use a table saw to taper the legs. (A taper jig comes in

handy here.)

• Arrange and mark table legs and rails clockwise according

to their locations on the finished product.

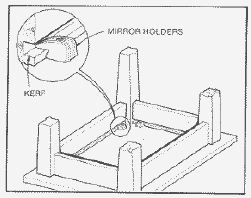

• To prepare the rails for attachment to the top, your plans

will specify exactly the dimensions of each piece. In our

example, the rails are cut 3 1/2' by 13 1/2' and 3 1/2' by

19 1/2'. There is a slot on the inside of each rail made by

a kerf cut to receive the mirror holder which holds the top.

It is 1/8" wide and 3/8" deep and begins 5/16" from the top

of each rail. You can use a router or a table saw to make

these slots.

Assembling the Top

The table top will be assembled from several individual

pieces of wood and glued together edge to edge. The three

pieces will be longer and wider than the dimensions

indicated in the plans. The top will then be cut to exact

specifications. Be certain that the edges are properly

jointed with no space between the boards. If done correctly,

the glue lines will be hard to

notice.

• Arrange the top boards so that the grain is pleasing to

you, then mark them according to their location. TThis

arrangement allows for any cupping or warping and ensures

the tabletop will remain flat.

• Joint the edges if needed. Use either a stationary or hand

jointer, both use a cutter that planes the edges smooth and

square, Note: If you don't have a jointer, a table saw is

the next best thing for smoothing rough edges. A hand

jointer plane does a good job, but requires a greater degree

of skill. Whichever method of jointing you use:

• Check your edges for squareness before you start gluing.

• Smooth out any roughness with sandpaper to your

satisfaction.

• Glue pieces together with yellow carpenters glue. This

glue is usually stronger than the wood itself. Place glue on

the piece evenly and on both sides. Once you have begun

gluing, spread it evenly across the joint and don't stop

until you are finished. Avoid getting glue on the surface of

the table.

• Put waxed paper on the top and bottom of the table t o

make sure the clamps are not glued to your tabletop.

• Apply clamps for pressure to make the tabletop as flat as

possible. Look for a slight squeeze out of glue which

indicates adequate pressure.

Note: If you plan

to use a planer to surface the top, the top will have to be

glued in two pieces, so that the pieces can fit through the

planer.

Note: Clamps can mar the wood. In addition to using the wax

paper, you may want to use scrap wood to protect the finish

of your table top by putting the clamp face on the scrap and

gently closing the clamp down. Care must be taken when you

slowly tighten the clamps, in case you change the alignment

of the table top.

• Once it has dried, (approximately 24 hrs.) remove the

clamps. If the surface isn't smooth use your planer or belt

sander. Scrape off any excess glue with a glue scraper being

careful not to dig into the top.

Assembling the Frame

There are many ways to assemble the frame. One of the best

ways is to attach the legs to the rails by using dowels

because of their strength. Dowels provide strength and

easier alignment and can be made of wood, metal or plastic.

Dowels can be pointed with spirals; or can have square ends

with no spirals. Use pointed dowels with spirals to take out

air pockets because they will set more glue and provide for

maximum stability.

The frame will be put together by using dowels. The dowels

are 3/8' diameter by 1 1/2" in length. The dowel holes are

2" apart (or the setting of the dowel jig) and begin 3/4"

from the top. The centers of the dowel holes should be

centered on the inside edges of the leg and rails.

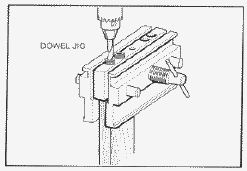

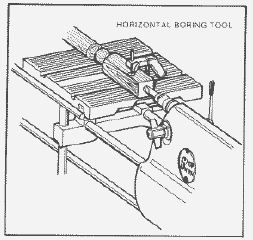

1. Drill dowel holes according

to the plans, using a dowel jig or a horizontal boring

machine. A dowel jig allows for accurate holes (directly in

the center regardless of the thickness of the wood) in both

the legs and rails. A piece of tape, or a depth gauge acts

as a guideline for the depth of the hole (half the length of

the dowel plus 1/4").

2. Apply the glue to the dowels, holes, and flat surfaces.

Tap the dowels in their length with a mallet. Clamp the side

rails and legs together.

3. Glue and clamp side rails to the end rails. At this point

check the frame for squareness by measuring on opposite

corners. If the measurements are the same, then your table

is square. Let the glue dry completely (approximately 24

hours).

Attaching the Top

1. Make sure tabletop is properly dried. Rip tabletop to

exact size.

2. Crosscut tabletop to exact size.

3. Use a belt sander until you have removed all traces of

glue and have a smooth finish.

4. To add the fancy edge, the videotape uses a router, but a

shaper or multipurpose tool could also be used. Start with

your end grain first to allow for a small tear out.

5. Draw lines on the underside of the table to make sure it

is centered.

There are two ways to attach the

top. The first is to use screw pockets, which attaches the

top to the rails. This requires using a brad-point bit with

a smaller bit to drill a pilot hole. You need at least two

screw pockets per side, for this table the total is eight.

Drill your pilot holes into the tabletop, and secure the top

with round head wood screws. Be careful not to go through

the top.

The other method uses mirror holders which attach the top to

the rails. Screwed into the underside of the top, these

holders project into a saw kerf on the rail. This table

requires ten holders, two for each end and three for each

side. To use mirror holders to attach the top to the rails,

locate and drill holes for the mounting screws and secure

tabletop in place. Be careful not to drill through top. Use

a drill press to set correct depth, or use a "stop collar"

on your hand drill. Never glue the top to the frame as this

does not allow for the expansion and contraction of the

wood.

Finishing the Assembled Table

Sanding

The best time to do any major sanding is BEFORE the main

pieces are attached. Sandpaper is graded as medium, or

numbers 60, 80, and 100. Fine sandpaper numbers are 150,

180, and very fine 220, 240, and 280. Medium is usually used

for the first sanding, fine for smoother results and very

fine for smoothing finishes between coats. Sandpaper can be

used wet for some finishes.

You can fill in nail holes with wood putty before sanding if

you are not planning to stain the wood. If you are staining,

fill the holes AFTER the stain is applied. In either case,

match the wood putty closely in color to the stock or use

saw dust and wood

glue to make your own putty.

1. Sand with a fine, wet sandpaper (start with a 120 grit on

plywood and 60-80 grit on other lumber) wrapped around a

felt pad or use a pad or orbital sander. Use aluminum

oxide sandpaper because its grit material lasts longer.

2. Sand slowly so you get the best job possible. Vacuum

frequently to remove dust. Finish manufacturers recommend

which grit of sandpaper to use with their specific finishes

to achieve the smoothest result. Feel the wood to check on

the smoothness as you work because touch is really the only

way to get a smooth surface. Make sure that you remove all

dust, finger marks and excess glue before applying the

finish. First vacuum or brush the entire piece clean and

then wipe with a tack cloth.

When it is time to varnish, vacuum the room and let the

remaining dust settle for 24 hours. Wear lint free clothes

and use the fastest drying varnish available. Use a tack rag

to remove dust before applying varnish and between coats. Do

not apply urethane varnish over a coat of shellac or

lacquer.

Applying Filler

(Optional Step) The key to a beautiful finish is making sure

the surface is as smooth as possible.

1. Countersink all nails and repair all dents.

2. Apply a coat of filler to all surfaces of the table.

(Paste wood filler thinned with turpentine or paint thinner

is best.) Filler is a compound mixed to the consistency of

yogurt which fills all the pores of the wood for a smoother

finish. Do not use the wood filler that is sold to repair

rotted wood. Work the filler into the wood instead of just

brushing it on. A short-bristled brush is best

and can be made from an old paint brush. Using the filler

gives your table that "Extra" touch of beauty by providing a

smoother finish. You can color the filler after thinning for

a perfect match of wood and filler.

3. Brush the filler on with the grain of the wood, making

sure all pores are filled.

4. Wipe off the first coat of filler. Recoat, this time

working across the grain. Make sure the brush is

heavily loaded with filler.

5. The instant the shiny wet surface looks dull, start

scrapping off excess filler with a straight, sharp edge

implement like a playing card, ruler, stiff cardboard or

knife with a wide blade (like the knife used to apply

drywall).

6. Use a rough cloth like burlap to rub briskly across the

grain.

7. Once the surface is as clean of excess filler as

possible, let it dry overnight. If you are using a wood with

an open grain, you may need two or three coats of filler.

Applying the Finish

Apply your finish in a well ventilated space with lots of

room. Cover the floor in the area that you will be applying

the finish so that if a spill occurs it will not leave a

permanent stain. Be sure the area is clean and dust free and

can remain so during the

drying period. Follow the manufacturer's instructions. The

finish is the first thing you and your friends will notice,

so take your time.

Our choice is a polyurethane finish applied with a foam

applicator. You could use an air compressor with a

spray attachment or the traditional brush method. Give the

surface a fine sanding between each coat for a long-lasting,

durable

shine.

Your handcrafted table is a personal source of pride and you

will want to select a finish which shows it off to its best

advantage. Here are some suggestions to consider when you

choose your finish.

1. Appearance: do you want a clear finish or do you want a

stain to blend with the other pieces in your home. Do you

prefer a high gloss or satin look?

2. Texture: Do you want the table to appear smooth and slick

or do you want to feel the wood's grain?

3. Durability and protection:

how is this piece going to be used, and what are you going

to set on it? Do you need minimum protection from water

marks and scratches?

4. Ease of application: how do you want to apply the finish?

Will you be using a rag, brush, or spray? Why not visit an

unfinished furniture store and talk to the staff about your

needs. Look at their finishes and don't hesitate to bring a

part of your project or a sample of a finish you may be

trying to match. Try any finish you are considering on a

scrap piece of wood that has been smoothed down to your

table's finish. You can save a lot of heartache by taking

the time to check BEFORE applying a finish that doesn't

work.

Another finish that can be used is an oil finish. The

advantage of the oil finish is that after the first coat a

fine grit of sandpaper can be used when wet (220) to cause a

slurry of dust particles and oil. This mixture is

continually absorbed into the wood

with each coat. Each coat builds up a very durable surface

with a hand-rubbed look. Though beautiful, those oil

finishes, do not have the durability and water resistance of

the polyurethane finishes.

Some refinishers use a sanding sealer, which makes a light

fuzz stiff so that it can be sanded off. Test to make sure

that a sealer will not adversely affect the finish by

applying to the underside of a shelf and then applying the

stain to see if it goes on

smoothly.

If brushing on the finish, consider the following:

1. Position the piece in horizontal sections.

2. Apply the paint, varnish or stain across the grain.

3. Brush out the finish with the grain using the brush as a

wiping tool. Clean the brush as it collects liquid.

4. Pull the brush across the table's surface with the

bristles held almost vertically.

5. Let each side dry between coats.

Check the varnish to see if a certain stain is called for.

Read the label for drying times and how many coats to apply.

Apply two, preferably three coats of urethane varnish using

a good quality natural bristle brush. Between coats wet sand

the finish. Rub the surface till it feels smooth. Wipe off

any residue and then apply the next coat. Be careful at the

edges of the table so varnish doesn't drip or run down the

sides. For the final touch, rub down the table using a thin

paste of rottenstone. Let the finish dry for a week before

buffing with a hard paste wax or lambs wool pad. Completing

this project gives you a beautiful addition to your home. It

is an expression of craftsmanship you and your family will

be proud of.

Tools: (Other than common shop

tools)

1. Table Saw

2. Jointer (optional)

3. A doweling jig or a horizontal boring tool

4. Jig saw

5. Router

6. Orbital sander

7. Shaper (optional)

8. Clamps for gluing

Materials:

1. Cabinet grade

plywood for carcass

2. Plywood for door, false front insert and kick plate face.

3. 1" x 6" oak for face frame

4. Dowels

5. Hinges

6. Knobs

7. Glue

8. Finishing nails (6d)

9. Flathead wood screws

10. Drawer materials and slides (if needed)

11. Sandpaper

12. Counter top materials

We hope you

enjoy this free woodworking plan and continue to visit our

site for more great plans. Our catalog is always

growing. Currently, our best value package is our

shed

plans package that contains thousands of woodworking

plans. Our categories are always available on

the left of your screen on any page of our site.

|