|

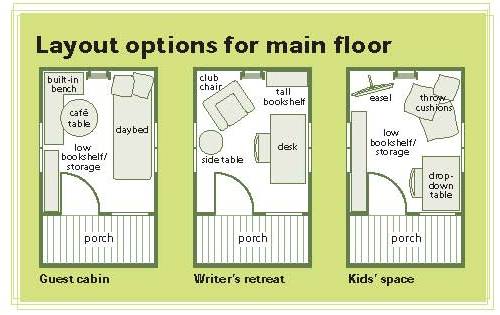

One of

the nicest things about a cottage is that it becomes

a place for friends and family to gather and share

memories. But the cherished kind of memory probably

doesn’t include the sound of Uncle Bob’s snoring, or

having to step over half a dozen nieces and nephews

on your way to a midnight snack. With a bunkie, you

can invite overnight guests and still have some

privacy at bedtime. And our Bunkie not only makes an

ideal guest cabin for cottage overflow, it also

doubles as a quiet retreat for those days when even

two’s a crowd (see “Layout Options For Main Floor,”

below).

When we designed this structure, we envisioned it as

suitable accommodation for a couple of adults and

three to four kids. A futon on the main level would

work well for a bed for the big folks, while cots or

an inflatable bed in the loft would be suitable for

the little ones. (Since a queen-size mattress will

fit, a couple of adults can also sleep comfortably

in the loft).

Our local building code requires a building permit

for any structure with floor space greater than 108

sq. ft. This bunkie was designed with that stricture

in mind: At 8' by 13'6", it is exactly 108 sq. ft.

and therefore, in most jurisdictions, does not need

that particular documentation. But check first: Some

municipalities require permits for anything over 100

sq. ft. Cottagers in those areas could modify the

plans – say, by reducing the length to 12'6" – to

fit the more restrictive rules. Even if a building

permit is not required, you must still check with

your local municipality and comply with zoning

bylaws (such as lot line and shoreline setbacks).

This is a big project, but not a very complex one.

In fact, if you built our

free outhouse plans, you will find this to be no

more challenging.

|

Materials List |

MATERIALS

PRESSURE TREATED LUMBER

16 at 2 x 6 by 8'

5 at 2 x 6 by 14'

SPRUCE LUMBER

6 at 1 x 3 by 8'

26 at 2 x 4 by 14'

12 at 2 x 4 by 10'

40 at 2 x 4 by 8'

11 at 2 x 6 by 8'

CEDAR

1 at 2 x 6 by 6'

2 at 6 x 6 by 12'

1 at 6 x 6 by 8'

1 at 4 x 4 by 8'

1 at 2 x 4 by 14'

1 at 2 x 4 by 12'

1 at 2 x 4 by 8'

2 at 1 x 6 by 8'

26 at 2 x 2 by 36"

70 lin.ft. 5⁄4 x 6" deck boards

PINE LUMBER

400 linear feet 1 x 10 rough-sawn pine

230 linear feet 1 x 6 T&G flooring

4 at 1 x 6 by 16'

8 at 1 x 6 by 8'

1 at 1 x 6 by 10'

4 at 2 x 4 by 12'

1 at 2 x 4 by 14'

1 at 2 x 4 by 8'

2 at 1 x 4 by 8'

2 at 1 x 3 by 10'

6 at 1 x 2 by 8'

PLYWOOD

3 at 5⁄8" x 4' x 8' T&G

LP CANEXEL SHIPLAP PANELS

11 at 7⁄16" x 4' x 8'

VICWEST SUPERVIC PROFILE STEEL ROOFING

14 at 30" x 93"

2 x 10' steel roofing ridge cap |

HARDWARE

1 bundle cedar shims (full size)

1 container outdoor glue

250 #9 x 31⁄2" deck screws

250 #8 x 2" deck screws

2 at 3⁄8" x 4" carriage bolts, nuts, and

washers

4 at 5⁄16" x 4" carriage bolts, nuts, and

washers

2 Anderson model 2N1630 double casement

windows

1 Anderson model N1624 casement window (RH)

1 Anderson model W2430 casement window (RH)

1 at 32" x 80" screen door and hardware

1 at 32" x 80" prehung pine entrance door

and hardware

4 at 3⁄8" x 6" carriage bolts, nuts, and

washers

2 at 5⁄16" x 8" lag bolts and washers

2 at 5⁄16" x 6" lag bolts and washers

100 #10 x 31⁄2" wood screws

20 #12 x 31⁄2" wood screws

1' medium link chain

2 quick links

1 brass snap

1 at 3⁄8" x 5" lagged eye bolt

1 at 3⁄8" x 5" threaded eye bolt,

nut, and washer

2 at 21⁄2" butt hinges

1 magnetic catch

2 lbs. of 2"galvanized nails for

Canexel panel

1 box of 11⁄2" screws for steel roof

1 roll VicWest underlayment

1 tube clear silicone caulk

2 tubes acrylic caulk (colour matched)

Foam screened insert for ridgecap |

|

Parts List |

|

Use |

Material |

Type |

|

FLOOR |

|

Joists and end

stringers |

16 at 2 x 6 by

8' |

PT |

|

Stringers and

solid bridging |

5 at 2 x 6 by

14' |

PT |

|

Bunkie floor |

2.5 at 5⁄8" x 4'

x 8' T&G |

PLY |

|

SIDE WALLS |

|

Posts and

headers |

2 at 6 x 6 by

12' |

CD |

|

Top and bottom

plates and blocking |

8 at 2 x 4 by

10' |

SP |

|

Studs (2 per 14'

piece) |

16 at 2 x 4 by

14' |

SP |

|

Bracing |

4 at 1 x 3 by 8' |

SP |

|

Window headers

(doubled) |

2 at 2 x 6 by 8' |

SP |

|

Canexel Shiplap

Panel |

5 at 7⁄16" x 4 x

8 |

PLY |

|

FRONT AND REAR

WALLS |

|

Studs (2 per 14'

length) |

9 at 2 x 4 by

14' |

SP |

|

Top and bottom

plates, wall blocking, and nailing edge |

10 at 2 x 4 by

8' |

SP |

|

Canexel

Shiplap Panel |

6 at 7⁄16" x 4 x

8 |

PLY |

|

PORCH/RAILINGS |

|

Header |

1 at 6 x 6 by 8' |

CD |

|

Newel posts |

1 at 4 x 4 by 8' |

CD |

|

Hand rails |

1 at 2 x 4 by

14' |

CD |

|

Hand rails |

1 at 2 x 4 by 8' |

CD |

|

Pickets |

26 at 2 x 2 by

36" |

CD |

|

Corner brackets |

1 at 2 x 4 by

12' |

CD |

|

Curved pieces |

1 at 2 x 6 by 6' |

CD |

|

Top plate |

1 at 2 x 6 by 8' |

SP |

|

2 x 4 nailing

edge |

1 at 2 x 4 by 8' |

SP |

|

Porch floor |

70 lin.ft. 5/4 x

6 |

CD |

|

Porch ceiling |

70 lin.ft. 1 x 6

T&G |

PN |

|

Trim (ripped to

1 x 2 and routered) |

1 at 1 x 6 by 8' |

CD |

|

LOFT |

|

Joists and solid

bridging |

8 at 2 x 6 by 8' |

SP |

|

Flooring |

150 lin.ft. 1 x

6 T&G |

PN |

|

Gate |

1 at 2 x 4 by 8' |

PN |

|

Lost Railings |

2 at 2 x 4 by

12' |

PN |

|

Panels in gate

and railings |

2 at 1 x 4 by 8' |

PN |

|

Railing shoe and

top rail |

2 at 1 x 2 by 8' |

PN |

|

ROOF AND GABLE

ENDS |

|

Rafters, 22 with

bird’s mouth, 4 without |

26 at 2 x 4 by

8' |

SP |

|

Gable framing |

4 at 2 x 4 by

10' |

SP |

|

Roof boards |

400 lin.ft. 1 x

10 |

PN |

|

VicWestSuper

Vic Profile |

14 at 30" x 93" |

ST |

|

Ridge cap |

2 at 10' |

ST |

|

LADDER |

|

Stringers and

ladder brackets |

2 at 2 x 4 by

12' |

PN |

|

Rungs |

1 at 2 x 4 by

14' |

PN |

|

Railings |

2 at 1 x 3 by

10' |

PN |

|

TRIM |

|

Fascia |

4 at 1 x 6 by

16' |

PN |

|

Corner trim |

8 at 1 x 6 by 8' |

PN |

|

Horizontal

lintel on rear wall |

1 at 1 x 6 by

10' |

PN |

|

Gable end trim |

4 at 1 x 2 by 8' |

PN |

FLOOR

Footings (six in all) will need to be in place

before construction can begin. I am partial to a

double rim joist at the base of structures like this

because of its greater strength, especially at

interlocking corners. And I like pressure-treated

(PT) lumber for any part of a structure close to the

ground – although, since the floor frame does not,

in fact, touch the ground, you could use ordinary

lumber.

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

1.

With the parts list (below) and Figures 1 and 2 to

guide you, cut all pieces for the floor frame to

length (wear a dust mask when you cut PT lumber) and

treat the cut ends. Lay out the joist locations –

16" on center – on the inner rim joists. Note that

the measurement to the center of the first joist

from the end must take into account the 3" thickness

of the double rim). Leave a 3⁄4" space between the

two laminated bunkie joists that sit at the 10' mark

and the first deck joist. This gap allows rain and

melt-water to drain between the boards.

2. Nail or screw the inner frame together. (The

3-1⁄2" deck screws in the hardware list are needed

only if you are screwing the frame together.)

Remember to keep joist crowns up; the crown is the

convex edge of a board when viewed from the end.

Nail or screw the outer rim joists to the inner

frame.

3. Cut bridging pieces to length and install between

floor joists.

Tip: When you measure for the bridging, take your

measurements between the joists where they are

secured to the rim, not in the middle. After

installing two or three bridging pieces, check the

cumulative measurement of bridging and joists and

compare with the measure at the rim joist to be sure

you’re not bending the joists out of line. Adjust

the next piece you install to compensate, if needed.

4. Two-and-a-half sheets of 5⁄8" tongue-and-groove

plywood are required to cover the floor for the

dwelling part of the building. Square up the floor –

diagonals must be equal – and screw the plywood to

the floor frame.

5. Level the floor frame, if required.

SIDE WALLS

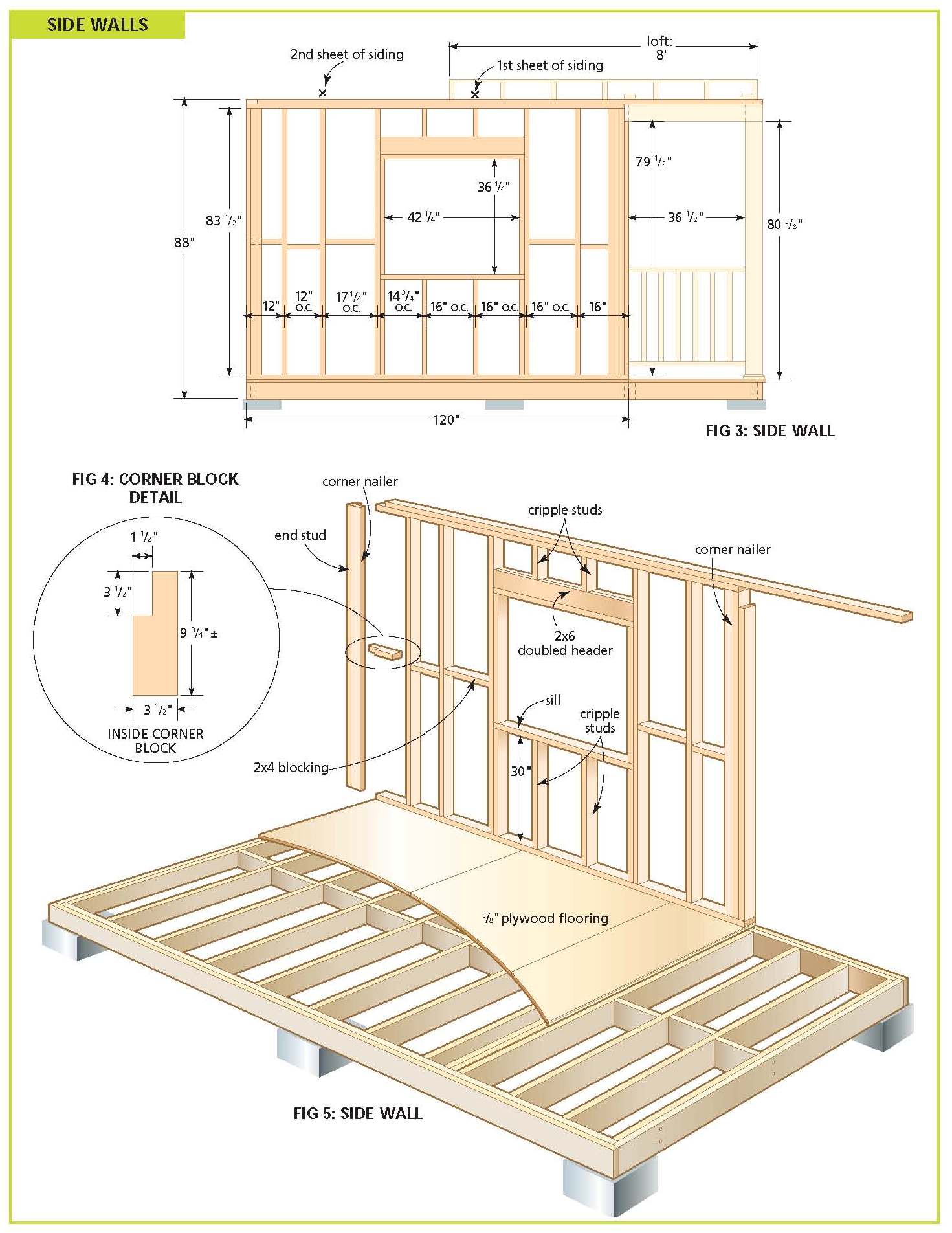

1. Cut the side wall pieces to length. Note that the

window headers consist of two 2 x 6s laminated

together with a piece of 1⁄2" plywood between as a

spacer. Also, the 6 x 6 by 43-1⁄2" side headers are

miterd 45° at the porch end and notched at the other

end (Figures 14 and 16). Drill two 1⁄2" holes –

preferably with a Forstner bit – in the face of each

side header, as in Figure 14. Drill clearance holes.

Cut eight 1⁄2" plugs and put them aside for now. (A

plug cutter is an inexpensive accessory available at

any lumber or hardware store. Use it to make your

own matching plugs from castoffs. Of course, there

are also commercially available plastic plugs.)

2. Lay out the stud locations on the bottom and top

plates as in Figure 3 (make sure that your layout is

consistent with the rough opening for your windows).

Note also that the centers are not all 16". When

siding, start from the porch end. The edge of the

second 4 x 8 sheet will line up with the middle of a

stud marked with an X. The remaining piece is 2'

wide (a 4 x 8 sheet ripped in half provides the 2'

pieces).

3. Nail or screw the wall frame together on the

ground, adding the double top plate last (lay out

the location of the rafters on the double top plate

first, starting from the porch end). Do not add the

6 x 6 side headers yet.

4. Cut the 2 x 4 blocking to length and nail between

the studs.

5. We selected Canexel 4 x 8 pre-finished panels for

this project for a number of reasons: sub-sheathing

is unnecessary, siding time is reduced, and they

look good. On the downside, there is a limited color

selection and the finish is only under warranty for

five years, so repainting could be necessary after

that. Cut five sheets to a length of 931⁄2"

(good-side down to avoid chipping on that side). Rip

one piece in half, lengthways.

6. Lay the sheets on the wall so that the edges meet

the top plate. Transfer the location of the rafters

on the edges of the sheathing. Remove the siding and

cut 11⁄2" by 53⁄4" notches where marked (see Figure

14). The siding panels will sit proud of the top

plate. These notches allow the rafters to sit tight

against the plates and also let the siding butt

against the bottom of the roof boards thereby

sealing the building from drafts. You can be a

little generous with the cuts as small gaps can be

filled with caulking.

7. Lay the siding pieces back on the walls, making

sure that the bottom edges are 3" below the bottom

plates (this lip can later be nailed to the rim

joist). Square up the frame and nail the siding to

the wall using 2" galvanized ardox nails, spaced

about 8" apart.

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

8. Find

two helpers. Stand each wall up in turn, being

careful not to damage the bottom edge of the panels.

Line up the bottom plates with the floor’s edges.

Screw or nail the bottom plates to the floor. Tip:

Don’t drive the nails home yet in case you need to

move the wall. Nail temporary braces from the end

studs to the rim joist. The walls should tip out

slightly at the top.

9. Add a 1 x 3 temporary, vertical brace at the

porch end (see photo), from the rim joist to the end

of each top plate. Insert the 6 x 6 side headers

into the space created when you framed the side

walls. Screw to the top plates and to the 2 x 4

studs. This is also a helper-assisted procedure!

through the top plate and into the side header where

indicated in Figure 16.

10. Drill a 1"-dia. by 2"-deep hole down through the

top plate and into the side header where indicated

in Figure 16. Drill a 5⁄16" clearance hole all

the way through.

11. If you have a reciprocating saw, cut out the

window openings from the inside. If you only have a

jig saw, drill holes through the paneling at each

corner, go outside, draw lines between the outside

radii of the holes, and follow the lines to cut out

the window openings.

12. Do not add the 6 x 6 posts yet.

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

REAR

WALL

1. Cut all the pieces and assemble the rear wall as

shown in Figures 8 and 9. Since there are no window

openings, cladding is simply a matter of nailing the

two 4' by 89" panels to the assembled wall. Make

sure that the top edges of the panels are lined up

with the bottom edge of the top plate, i.e., between

the two plates.

2. With a helper, lift the rear wall assembly into

place. Nail or screw the bottom plate to the floor.

Nail or screw the corners together. Nail the 3-1⁄2"

overhangs to the side wall end studs. Nail the

bottom edge of each panel to the rim joists.

FRONT WALL

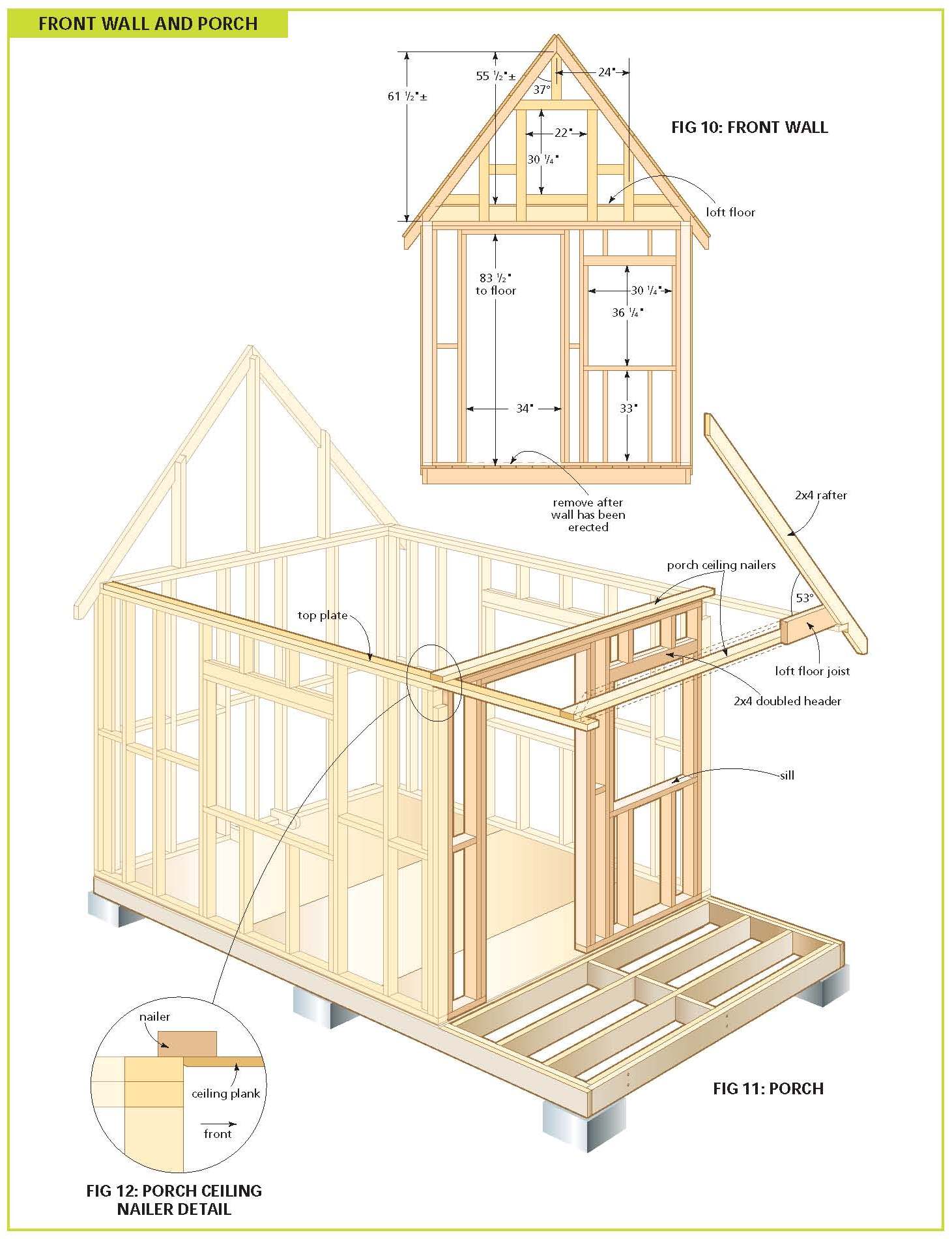

1. Cut all front wall pieces to length (see Figure

10). The header over the window consists of two

pieces of 2 x 4 laminated together. Since the front

wall is not a load bearing wall, the header over the

door consists of a single 2 x 4 on the flat to

provide the correct dimension for the entrance door

rough opening.

2. Nail or screw the frame together. Note that the

piece in the bottom plate, where the door is

located, will be removed after the assembled wall is

in place.

3. Trim two sheets of siding to 91".

4. Lay one panel on the wall over the door opening,

noting that the top edge should be flush to the top

of the double top plate,

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

and the

left side should be 3-1⁄2" past the end stud (this

lip will be nailed to the sidewall end stud). Square

everything up and tack the sheet in place. Have a

helper lift the upper end of the wall up off the

floor, high enough so that you can trace the opening

for the door. Lay the wall back down, remove the

sheet and cut out the opening for the door. While

you’re at it, cut out notches for the 6 x 6 side

header and for the rim joists (include the thickness

of the plywood floor in this calculation).

5. Lay the panel back down and nail it to the frame.

6. Lay the other sheet on the frame and nail it

down.

7. Remove the two braces from the side walls and,

with a helper, lift the front wall into place. Nail

or screw the bottom plate to the floor. Nail or

screw the corners together. Nail the 31⁄2" overhangs

to the side wall end studs. (If the floor is level

and the walls are square then, when assembled, the

walls should be plumb.)

8. Before you can cover the porch ceiling, you will

need to scab a 2 x 4 nailer to the top of the front

wall double top plate to act as a nailing edge (see

Figure 11). It should extend about halfway over the

leading edge of the double top plate.

9. With all four walls in place, drive the bottom

plate nails home, cut out the openings for the front

window and door, and then cut out the sill space for

the door opening.

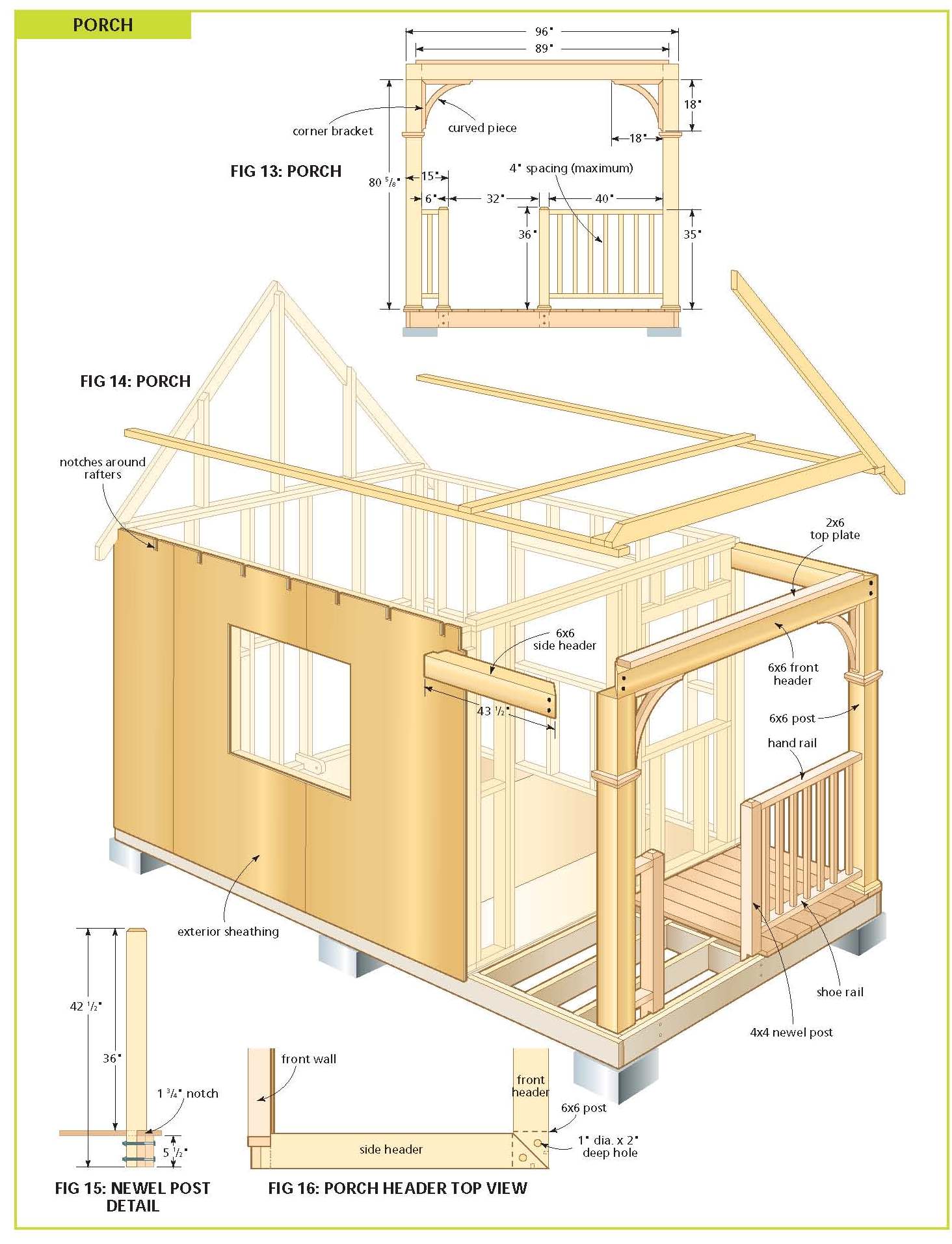

PORCH

I chose cedar for the front porch – despite its

rather steep cost – chiefly because it is hard to

find 6 x 6 pine (my preferred material). PT is a lot

cheaper but far less attractive than cedar, unless

painted or stained.

1. Cut the 5⁄4 x 6 deck boards to length – allowing

for 1" of overhang at the front – and nail or screw

to the joists. A clearance hole may be needed at the

board ends to prevent splitting. Begin in the centre

and work your way out evenly to both sides, leaving

a 3⁄8" gap between the boards. The last two boards

may have to be ripped – make sure to leave a 1"

overhang as well. If you were careful, each end

board should be the same width.

2. Cut the two 6 x 6 porch posts and the front

header to length; the header is mitered at both

ends. (Mitering the 6 x 6 is a bit of challenge if

you do not own a 12" compound sliding miter saw:

Mark your cut line, then take passes with a circular

saw from either side. There will likely still be a

sliver of wood in the middle that you’ll need to

clear with a handsaw.) Drill two 1⁄2" holes, 3⁄4"

deep in the end faces, as in Figure 14.

3. Stand the end posts in place. Lag the 6 x 6 by

431⁄2" side headers to the tops of the posts with

the 8" lag bolts. Plumb the posts and toenail to the

floor, keeping the nails or screws below the line of

the trim (about 2"). For added strength, you can

also drive a few screws up into the post end from

the underside of the deck boards (though it’s a

little tricky, considering that the piers may be in

the way!)

4. Lift the 6 x 6 by 8' front header into place.

Attach it to the side headers with outdoor glue and

the #12 x 31⁄2" screws. Plug the holes (glue the

plugs in place and trim them after the glue dries).

5. Add the 2 x 6 top plate and screw or nail it down

to the front header. Drill a 1" hole about 2" deep

down through the 2 x 6 into the top of each end of

the 8' header . Drill a 5⁄16" clearance hole as in

Figure 16. Lag the 8' header to the end posts. Also

screw the side wall 2 x 4 top plate to the header

using #8 x 3" screws with clearance holes to

minimize splitting.

6. Screw or nail the 2 x 4 nailing edge to the 2 x

6, as in Figure 11.

7. According to our local codes, a deck does not

need a railing if it’s less than 2' above grade. For

decks higher than that, the railing must be no less

than 35" high. If the deck is higher than 5'11"

above grade, then the railing must be 42" high. If

you are installing the optional railing assemblies,

start by notching the newel posts, as in Figure 15.

Determine where the newel posts will be situated and

mark 13⁄4" by 31⁄2" rectangles on the deck boards.

Remove the marked boards and cut out the rectangles

with a jigsaw. Replace the boards, fit the newel

posts into the holes, and clamp in place. Make sure

that, once installed, the railing assembly will fit

tightly against the newel and corner posts. Drill

two 3⁄8" holes through the rim joists and each newel

post. Insert the 3⁄8" x 6" carriage bolts, add the

washers and nuts, and tighten.

8. Cut pickets to length (36" or 38", see below) and

router all four edges with a roundover bit. Screw

the pickets to the handrails. I suggest covering the

screws with 3⁄8"-plugs on the top handrail for a

more attractive finish. Drill pocket holes (with a

pocket-hole jig) slightly angled out on the

underside of the handrail ends and secure them to

the posts. Router the handrail and shoe rail edges,

top and bottom, with a roundover bit. To keep the

pickets from turning, glue them in place.

9. Cut out and assemble the brackets (see Figure

13). Locate and attach to the posts and headers with

eight #8 x 2" screws per bracket. If you’ve plugged

all of your holes so far, then don’t neglect to do

so now (this requires 3⁄8" plugs).

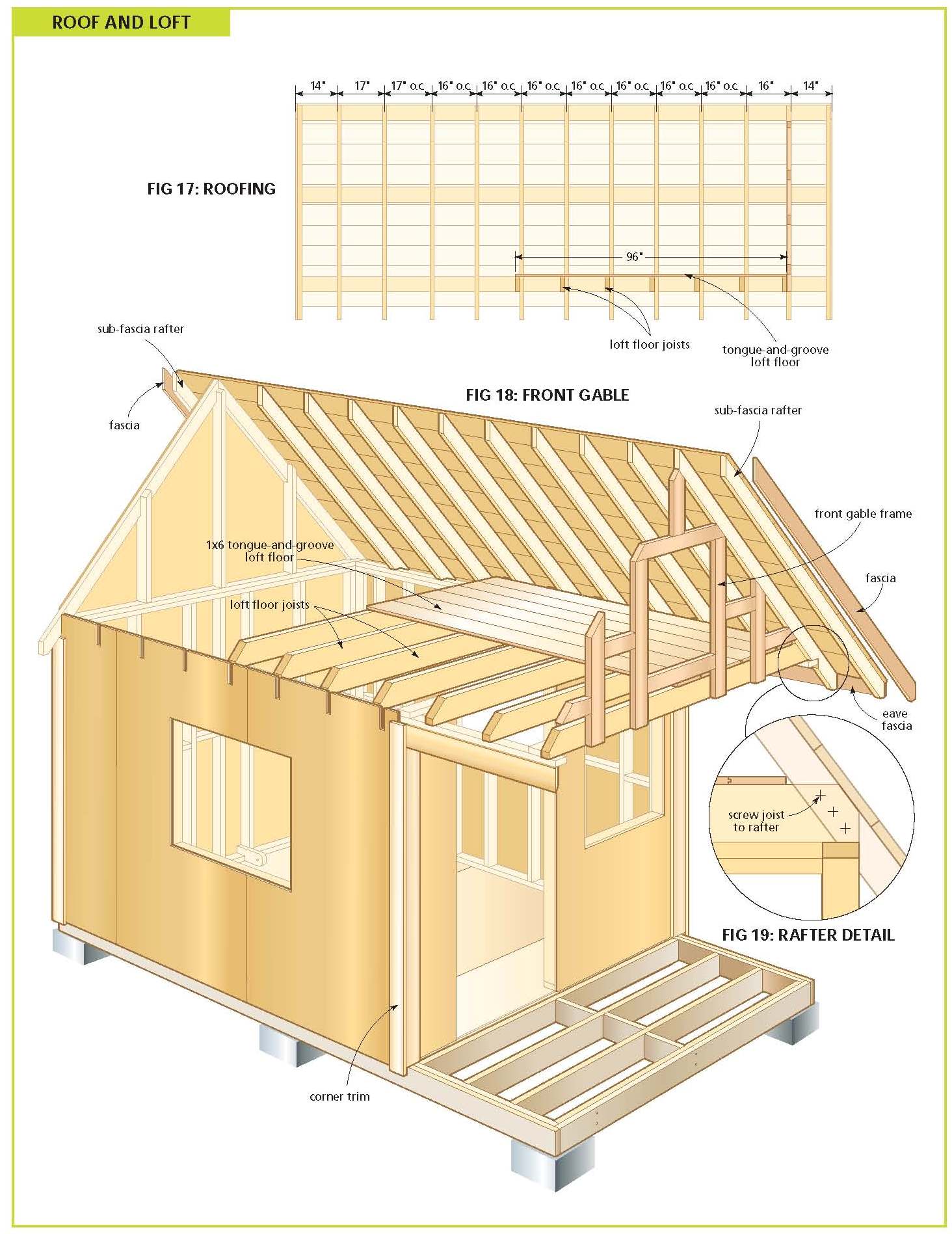

LOFT

The loft joists are located on the inside of the

roof rafters, as in Figure 17. The rafters will be

screwed or nailed to the joist ends later.

1. Cut the loft joists to length and trim the

corners as required. Set the joists in place and

toenail to the top plates.

2. Cut bridging pieces to length and install between

the loft joists, as in the floor construction. The

loft floor, as well as the railing and gate

assembly, can be installed once the rafters have

been installed (see roof instructions).

3. Next, you need to finish off the ceiling of the

porch area with pine tongue-and-groove. Cut the

boards to length and attach to the two nailing

boards and to the underside of the loft joists in

the porch ceiling. You will have to add trim around

the inside perimeter to hide the gap left over the

headers. (The trim is not needed on the front wall,

but makes for a more finished appearance. Add only

after the siding has been installed). This is the

same trim that you will use for the foot of each

corner and newel post.

RAFTERS AND GABLE ENDS

1. Lay out and cut the rafters as in Figures 6 and

7. Note that 22 have a bird’s mouth, while four do

not. Now, 53° might seem like a rather arbitrary

angle for rafters, and it is. It was born out of the

necessity to gain as much room as possible in the

loft and from the fact that my miter saw will cut

angles as great as 65°. So, after a number of

drawings we determined that 53° would give the most

pleasing appearance as well as maximize loft height.

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

2. Set

opposing rafters in place on the top plates,

beginning at the porch end. The first seven sets sit

tight to the loft joists (the leftover piece of

plywood laid on the loft joists serves as an

excellent temporary floor). There is no ridge board

in this plan so the rafters will butt up against

each other. Screw or nail the rafters together at

the peak, toenail to the top plate, and nail or

screw to the joist – where applicable.

3. Plumb up the last set of rafters, bracing them

from the inside of the back wall. Temporarily nail

or screw a couple of 1 x 3s to the rafters to hold

them parallel. Check the spacing between the sets

and check that the first set is also plumb and that

the overall distance is 13'6". Make adjustments as

you go.

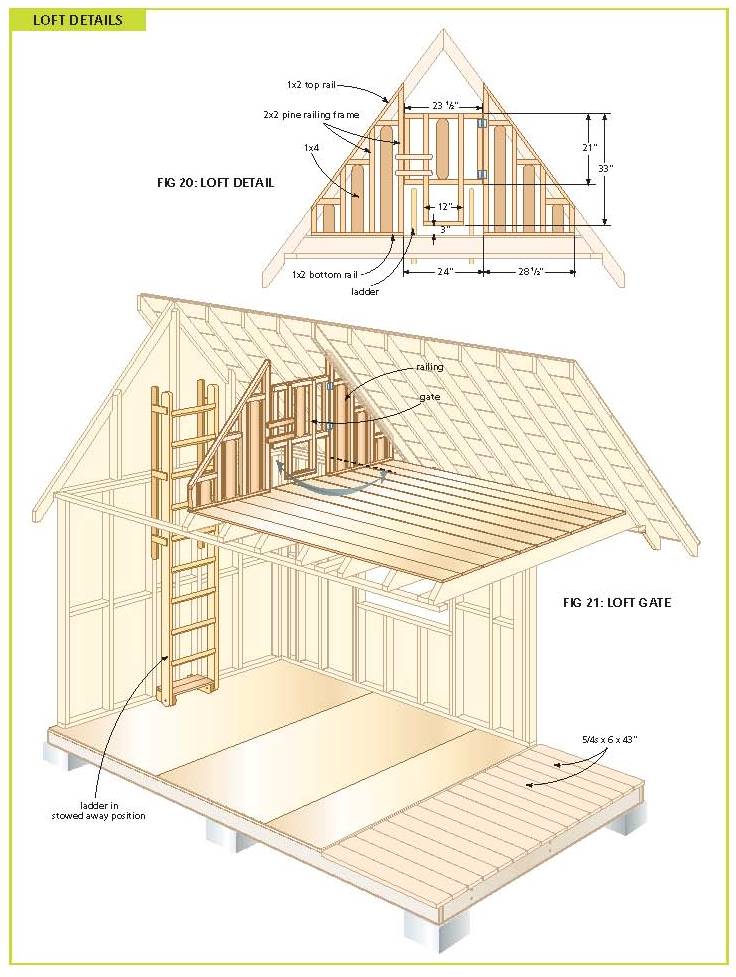

4. Now you can go back and finish off the loft

floor, as well as the railing and gate assembly. For

the pine tongue-and-groove floor, start with the

groove edge of one 96" piece tight to the rafters.

Nail through the tongue diagonally into the joist.

Proceed until you reach the other rafter. Cut short

pieces to fill between rafters and create a seal

between the floor and the roof boards. Nail in place

(it is a good idea to add a nailing strip to the

rafter face as well).

5. Figure 20 shows details for the loft railing and

gate (the view is from the inside of the loft

looking towards the rear of the bunkie). If you plan

to move a large mattress into the loft, hold off on

building this until the end, after you get the

mattress in place. This railing consists of pieces

ripped from lengths of 2 x 4 pine (some retail

outlets sell 2 x 2s) and 1 x 4 boards. There is a

24" gap for a gate in the middle for entry and

egress to the loft via the ladder. The 1 x 2 bottom

rail makes it easy to secure the railing assembly

neatly to the loft floor. The gate swings into the

loft space with two short 1 x 2 pieces acting as

stops. A magnetic catch holds the door closed.

6. Frame the gable ends (Figures 9, 18, and 19). It

is unusual to use 2 x 4s on their faces in the

manner shown in Figure 18 for the front gable, but

it works well in this instance. The gable end with

no window should be framed in the traditional

manner.

7. Side the gable ends. One sheet will do for each;

however, the sheets are too big to handle, so I

suggest doing the layout and cutting on the ground.

Keep in mind that you want the siding to extend 1⁄2"

down onto the 6 x 6 header. You can use the offcuts

from the porch end to fill in the back end, and vice

versa.

8. With a helper working from the loft, lift the

4'-wide, precut centre piece up into place in the

front gable. Tack in place and get your helper to

trace the window opening. Bring the piece back down

and cut out the window opening. Lift the piece back

up into place and nail to the rafters and gable

frame. Nail the end pieces into place.

9. You should also nail filler pieces of siding

between the rafters that sit on the 6 x 6 side wall

headers, bearing in mind that they must be wide

enough to meet the top edge of the rafter and extend

1⁄2" down onto the side-wall headers.

10. You will only be able to add the subfascia

rafters, at the front and back of the roof, once the

roof boards have been nailed in place (Figure 18).

ROOF

1. Starting at the rafter tails and working your way

up, nail the roof boards to the rafters, good side

down, three nails per rafter. The gable overhang

should be 131⁄4" (install long, measure, snap a

chalk line, and cut when the boards are already

nailed down).

2. Screw the sub-fascia rafters to the roofboard

ends.

3. Measure, cut, and nail the eave fascia to the

rafter tails (see Figure 18). The two gable end

tails need to be perfectly vertical.

4. Now cut the pieces for the gable end fascia. In

the middle of two 1 x 6 by 16' boards, make the 37°

cut for where they meet at the peak. Temporarily

tack them in place to the sub-fascia rafters and

trace the line where these meet the eave fascia.

Remove and cut off this piece. Nail to the

sub-fascia rafter and to the eave fascia.

5. Staple the roofing underlayment to the roof

boards, beginning at the bottom.

6. Cut the steel roof panels to length with a

metal-cutting blade in your circular saw. Make sure

you use a straightedge guide.

7. Install the panels with the cut edge towards the

peak, overlapping each panel with the next, by about

1". We used 11⁄2" screws to avoid strapping. (Do not

overtighten as the screw tips will pierce the roof

boards. If any do poke into the loft space, file or

cut off the tips with a mini-grinder.) Rows of

screws should be 2' apart. You will have to overlap

the last panel.

8. Install the ridge cap. You’ll have to cut one of

the ridge cap pieces to length – don’t forget to

leave extra length to allow the pieces to overlap

each other.

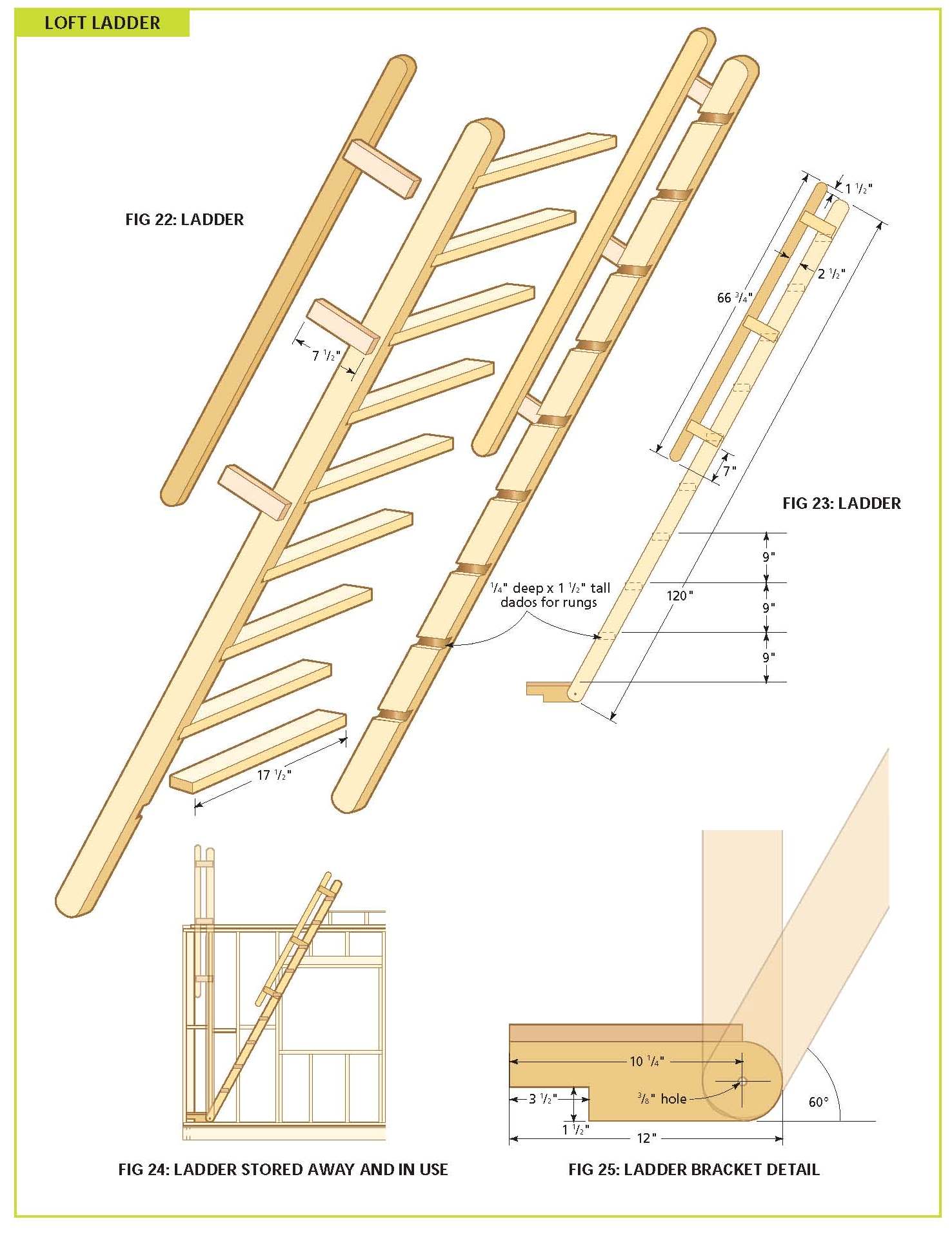

LOFT LADDER

1. Cut the two ladder stringers and brackets to

length from the 12' lengths of 2 x 4 pine (see

Figure 23). The rungs are cut from a 2 x 4 by 14'.

Using a jigsaw, round the ends of the stringers and

the brackets.

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

Router

and sand the outside and inside perimeters of the

stringers and rungs with a roundover bit.

2. Lay out the rung pattern on the stringers (the 9"

rise is something of a compromise between a stair

riser – about 8" – and a ladder rung – about 11".

(It also makes the last step 9" below the loft

floor). Remember that the pattern will be opposing.

Cut 1⁄4" by 11⁄2" dados into the stringers to accept

the rungs, as in Figure 22.

3. Drill 3⁄8" holes in the ends of the stringers and

in the ladder brackets where indicated (Figure 25).

4. Assemble the ladder using #9 x 3" screws and wood

glue. (Fill the holes with plugs if you’ve done so

elsewhere.) Make sure construction is square before

the glue sets.

5. Cut handrails and handrail brackets to length as

in Figures 22 and 23. Round the ends of the

handrails and router both inside and outside

perimeters.

6. Secure the handrail brackets by glueing and

screwing them to the outside of the stringers (with

#8 x 2" screws). Glue and screw the handrails to the

inside of the brackets (with #8 x 11⁄4" screws).

7. Set the ladder brackets in place on the inside of

the appropriate studs (Figure 9) and drill two 5⁄16"

holes through each bracket and stud. Fasten the

brackets to the studs with two 5⁄16" x 4" carriage

bolts, washers, and nuts (with the nuts on the

inside). 3⁄8" x 4" carriage bolts, washers, and nuts

(again, with the nuts on the inside).

8. Secure the ladder to the brackets with the 3⁄8" x

4" carriage bolts, washers, and nuts (again, with

the nuts on the inside).

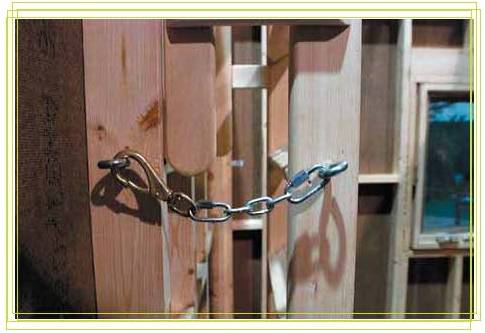

9. Lean the ladder against the wall. Screw a 3⁄8"

eye bolt into the ladder stringer and into a rung (a

pilot hole is essential). At the same level, drill a

3⁄8" hole through the closest stud (see photo,

above). Insert a threaded eye bolt into each hole

and add a washer and nut. (If you need to cut the

bolt to length, file the end smooth.) Use a quick

link to attach one end of the correct length of

chain to the eye bolt in the ladder. Use another

quick link to attach a snap to the other end of the

chain. Snap to the eye bolt in the stud and, voilà,

the ladder is secured. You may have to play with the

chain length until you are satisfied.

10. Unhook the snap and lean the ladder against the

loft. Cut two pieces of pine tongue-and-groove

board: 1" x 6" by 17". Screw or nail to the top of

the brackets (Figure 25). These boards form the

first step. (If screwing, it is a good idea to drill

clearance holes to minimize the risk of splitting.)

The boards should not extend out over the curve of

the brackets.

WINDOWS

We used Anderson windows. I also opted for pine

frames and brick-stop mouldings. In this instance,

because of the flat siding product we used, the

windows can be installed over the siding.

(Generally, windows are installed first and then

siding butts up against the frame.)

1. Set the windows in the spaces provided (this is

usually a two-person job – one holder, one

installer). Shim for plumb and level.

2. Nail or screw into the sill and studs only,

through the shims, and into the 2 x 4 frame. Again,

3⁄8" holes and plugs should be used for appearance

if using screws.

3. Since the windows I have selected come complete

with brick-stop moldings, these can be nailed into

the 2 x 4s as well. (To reduce drafts, you should

caulk around these later with a paintable or colored

caulk.)

4. Carefully trim away the shims. Note: The windows,

door, siding, and roofing materials are all

special-order materials. Allow 2–3 weeks for

delivery.

DOOR

1. If the entrance door you select is prehung

(always the better option), then installation is

straightforward. Remove the pins from the hinges and

lift the door out of the frame. Sit the door frame

in the opening. (Note that you will need to add a

strip of 3⁄8" plywood to the underside of the sill

to bring it level with the deck boards.) Level the

top jamb, shim, and plumb up the hinge-side jamb.

(Shims on the hinge side should be situated behind

the three hinges.) Shim and plumb up the strikeplate

jamb, keeping it parallel to the hingeside jamb.

(Shim in three places as well, making sure to place

one set of shims behind the strike plate.) When you

are satisfied, nail in place. Hook the door back

into the hinges, add the pins, and check that it

operates smoothly. Tip: For a more secure

installation, remove one factory installed screw –

the middle one – from each jamb hinge and substitute

a longer one that will pass through the shims and

well into the 2 x 4 trimmer.

2. Some pre-hung doors come complete with brick-stop

moldings already installed. If not, you will have to

cut and nail the trim to the door jambs.

3. Installing the screen door may require mortising

the hinges. (I recently acquired a $50 mortising jig

for my router and it performed exceedingly well.)

However, the door from Beyond The Screen Door

actually mounts to the brick stop molding, so I used

face-mount screen door spring hinges.

TRIM AND FINISHING

1. Since few places sell cedar trim, you will most

likely have to fashion your own. Rip one 2" strip

and two 11⁄2" strips from the 1 x 6 by 8'. Add a

routered profile of your choice. (Use the same

profile for the porch ceiling trim.) Miter and nail

2" trim around the base of the corner and newel

posts. Repeat below corner brackets as in Figure 14

with the 11⁄2" trim.

2. Trim the inside perimeter of the porch ceiling

with 11⁄2" trim.

3. Measure and trim the 10' length of 1 x 6 pine,

and nail over the sheathing on the rear wall. Centre

it more or less on the line that divides the

sheathing so you can nail into the framing below and

above the top plates. Add a bead of caulk along the

top edge as a water barrier. (To harmonize wood

types, you could expand your budget and select 1 x 6

cedar for the trim instead of pine.)

4. For the corners of the building, we used 1 x 6 to

maintain a balance with the 6 x 6 posts, giving the

structure a kind of faux timber- frame style.

Consequently, one of the two pieces used for each

corner will have to be ripped to 43⁄4".

5. Where the siding meets the roof boards in the

gable ends, trim with 1 x 2.

6. All exterior wood surfaces should be given a

protectant finish.

7. Caulk where required (around the windows, door,

and where the top of the siding meets the rafters

and the roof boards).

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|

Free

Wood Cabin Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|