|

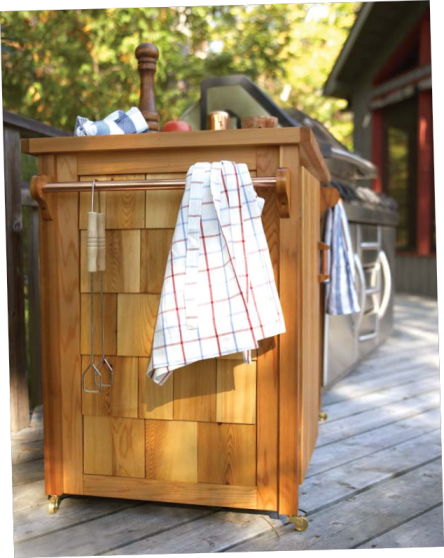

I love

outdoor cooking, but it does bring up one of life’s

profound mysteries. At the house, there’s a

wide

open lake, acres of empty land nearby, and never

more than a small crowd of people around. So much

outdoor space to use and enjoy, and it all somehow

disappears in front of the barbecue. There’s just

never enough room for preparing food or getting it

from the grill onto plates. The side tables on my

’cue will barely fit a single plate or a couple of

spice bottles.

In the kitchen, an island gives that fl at, stable

surface, versatile counter space with all-around

access. This outdoor work center offers the same

utility, and stands up to the elements. With storage

for charcoal or propane along with barbecue tools,

and a design that allows for personalization, this

island puts outdoor space where it’s needed.

This project uses 1x6 cedar fence boards (which are

actually " by 5 "), 2x2 cedar spindles (again, in

real life these are 1 " square), and construction

grade spruce plywood. While it may look complex to

build, the modular construction and pocket-hole

joinery make this project suitable for all skill

levels. The only tools required are a table saw,

drill, miter saw or hand saw, a pocket-hole jig, and

a hot-glue gun.

|

MATERIALS

All wood is 3/4"-thick cedar, except where

noted.

Front and rear

4 rails: 2" x 30"

2 long stiles: 2" x 31"

2 centre stiles: 2" x 27"

4 legs: 1!/2" x 1!/2" x 31"

Panels

Side and center panels:

20" x 31", !/4" spruce plywood

4 long stiles: 2" x 31"

4 side rails: 2" x 16"

Rear panel: 16!/2" x 31",

!/4" spruce plywood*

2 end rails: 2" x 20"

1 bundle cedar shims

Top

Countertop base: 24" x 36",

3/4" spruce plywood*

Countertop edges:

2 each of 1¼" x 24" and

1¼" x 37!/2"*

Door

3 pieces: 5!/2" x 30 "

Cabinet bottom and shelves

4 bottom cleats: 3/4" x 20"

2 middle cleats: 3/4" x 183/8"

4 shelf edges: 1!/2" x 18!/2" *

Floorboards: leftovers

Shelf slats: leftovers

Hardware

!/2" copper pipe

3/4" copper pipe

1 pair hinges

4 casters

4 brass hooks

Shelf support pins |

|

|

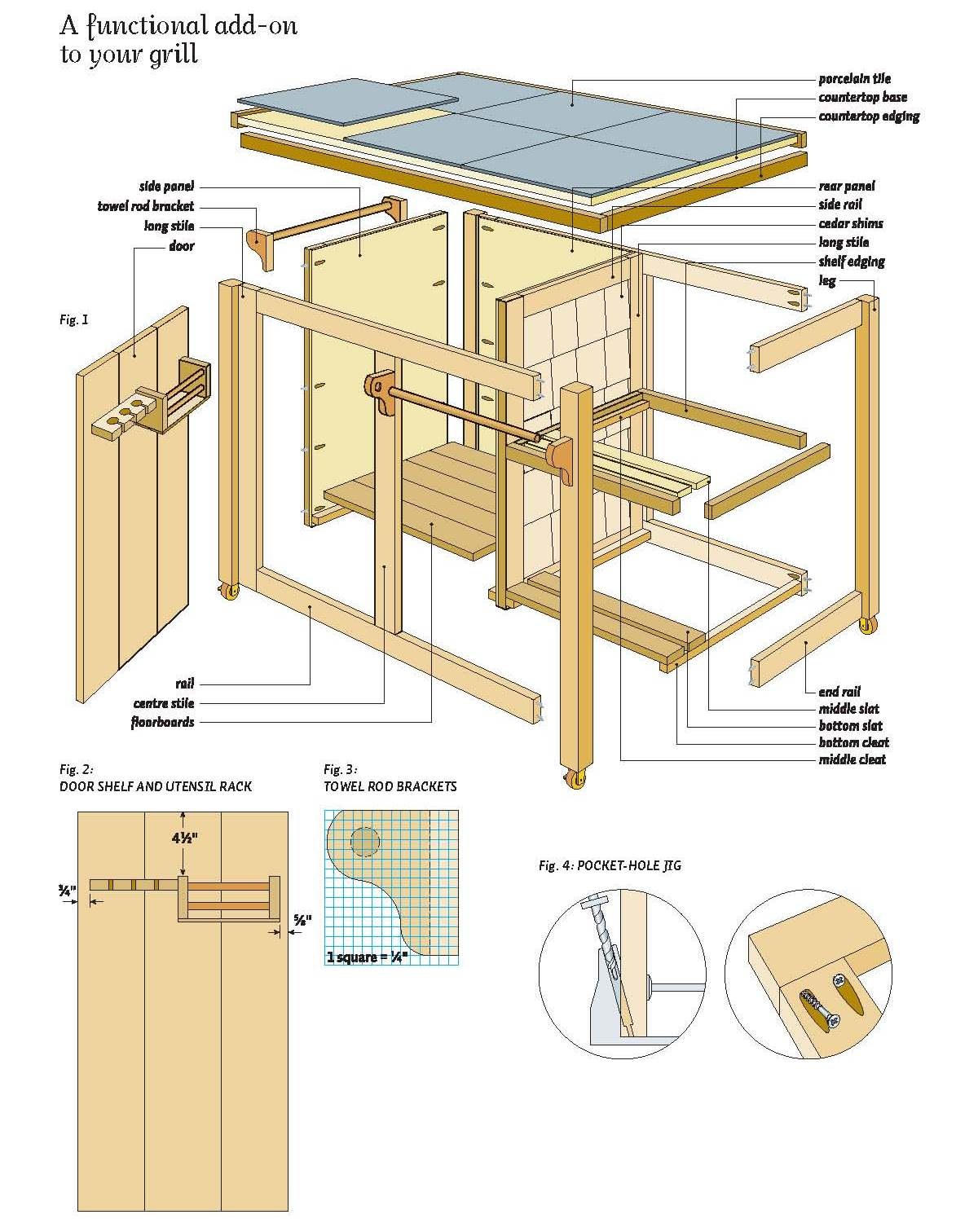

Begin with

front and rear assemblies

1. Rip your fence boards into 2" strips on the table

saw, setting the off cuts aside to use later.

Crosscut the four stiles and rails to length, then

drill two pocket holes into the backside of each end

of the four rails and the two shorter stiles.

Next, cut four sections of 2x2 cedar spindles to 31"

to make the legs, and get ready to assemble the

frames.

2. Working with the components face down on a large

table or the floor, attach the top and bottom rails

to the long stiles, making sure the top edges are

flush. Next, fasten each centre stile in place,

leaving 14" between it and the long stile. Finally,

fasten the frames to the legs. The rails at

the open end are attached to the legs with

pocket-hole screws, while the end with the stile is

just glued in place using outdoor-rated wood glue

and clamped until dry. Because the legs are 1 "

thick, there will be a " off set from the stiles and

rails. Attach the legs so they are flush on

the back side, making sure that the front and rear

assemblies are mirror images of each other.

Make two panels

1. The framed cedar-shake panels that join the front

and back assemblies look great and are very easy to

make. Cut two pieces of " spruce plywood to 20" by

31". Cut the stiles and rails that frame these

panels, and glue and clamp them in place on the

plywood. As back-up for the glue, drive a few "

screws or finishing nails through the ply and into

the cedar.

2. The shakes filling the frames are actually cedar

construction shims adhered with hot glue. Starting

with a double layer at the bottom, test-fit the

shims, and trim to width with a straight edge and

utility knife. I left a gap, just eyeballed,

of about 1⁄8" between them. Once the pieces for the

bottom row are cut, glue permanently in place with a

couple of beads of hot glue, then repeat the process

four times, trimming to width (and length where

necessary) to make up the five rows of shakes,

spacing the rows 5 " apart. Be careful to off set

the shakes, so one vertical gap doesn’t line up with

the one below.

More pocket holes

1. The two panels attach to the front and rear

frames with more pocket screws. Drill four or five

evenly spaced holes down each side of the

panels--putting the holes on the plywood side, of

course. Apply a thin layer of outdoor-rated wood

glue down the edges of the side panel and then

secure it in place between the front and rear frames

with the pocket screws. Attach the centre panel the

same way, making sure it is centered on the stile.

2. Attach two more rails at the top and bottom of

the open end. Cut to length, drill two pocket holes

(from the back) per end, and secure between the

legs.

3. The rear panel is just a 31"-long piece of

plywood trimmed to fi t between the side and centre

panels (16 1⁄2" in my case, but measure first for a

perfect fit). It’s glued in place, secured with

pocket-hole screws from inside the cabinet, and then

the outside is covered in shims, applied the same

way as with the other panels.

Bottom and top

1. The cabinet floorboards are simply more ¾ " cedar

pieces, sitting on ¾ " by ¾ " cleats that are glued

and nailed to the bottom of the cart, ¾ " below the

top edge of the rails. The width and spacing of the

boards isn’t crucial here, so just use what you have

on hand and trim your boards to length. Evenly space

the slats and nail them to the cleats with 1¼ "

finishing nails.

2. The countertop base is ¾ " plywood, cut to the

exact dimensions of your tiles, then screwed in

place with #8 x 1½ " wood screws driven through the

top and into the frame of the cabinet. While I

really wanted the look of slate tiles, I chose to

use porcelain tiles for this surface instead.

Porcelain tiles are durable and far more uniform

than slate tile would be, but still have a look and

texture similar to natural stone. Because porcelain

tiles, unlike ceramic, are moisture-proof, they’re

not affected by freezing, though I wouldn’t leave

the work centre out all winter. Note: Don’t trust

the sizes on the tile box. Mine were listed as 12"

by 12", but they actually measured closer to 11¾ "

square. Lay out all of your tiles on an oversized

piece of plywood and trace the outside for an

accurate measurement.

3. To finish up the top, glue the tiles in place

with clear silicone caulking and edge the top with

some of the off cuts you set aside earlier. Trim

them to length and hold in place with wood glue and

1½ " finishing nails. It is a good idea to also

apply a small amount of silicone to the edges of the

tiles as you put them in place. By gluing the tiles

together like this, you’ll prevent water from

leaking into the small cracks between the tiles and

possibly harming the plywood substrate. The door The

door starts as three 30" lengths of 1x6, edge-glued

and sanded fl at. Choose the flattest, straightest

pieces you can find, and clean up the mating edges

with a pass on the table saw, or a few strokes of a

hand plane, to ensure a good fit between boards

before gluing. If desired, you can add two rails,

secured with screws to the back of the door, to

ensure it stays fl at. Once the door is built, trim

it to a final size of 15" by 28"and hang it with a

pair of brass or stainless steel standard cabinet

hinges.

Final touches

1. This is the fun part. Use the scraps and any

stuff you have lying around the cottage, along with

a healthy dose of imagination, to make up shelves,

holders, handles, and custom touches to suit your

needs. My handles and towel rods are made of old

copper pipe that I cleaned up with fine steel wool

and sealed with a coat of clear lacquer. I cut their

support brackets to a pleasing shape with a jig saw,

then drilled 3⁄8"-deep holes in them with a Forstner

or spade bit. The blocks, with pipe in position, are

glued and screwed in place. Two notes: Because the

right front leg sits proud of the stiles, its

bracket needs to be ¾ " shorter than the others.

Next, drill the holes 1⁄8" larger than the nominal

size of the pipe for a good fi t. For ½ " pipe, you

need a 5⁄8" hole; for ¾ " pipe, you need 7⁄8".

2. The shelf and rack inside my door can hold spice

bottles, a barbecue igniter, and various tools and

baskets. To make the rack, I used a 2" by 6¼ " piece

of scrap, into which I drilled three 7⁄8" holes and

then cut slots with a handsaw. The shelf consists of

two 3" by 3" blocks joined together with 6½ "

lengths of ½ " copper pipe, and two 1¼ " by 7 ¼ "

strips of ¼ " scrap nailed to the bottom. The parts

are then attached to the door with glue and, you

guessed it, pocket screws. Under the rack, I also

installed four solid brass hooks for added storage

options.

3. The middle shelf is made entirely of scrap left

over from cutting the 2"-wide stock earlier. Build a

frame with pieces standing on edge to fit inside the

opening, then attach the slats with a couple of

cleats and some finishing nails. You can attach the

shelf permanently with four 1½ " screws or, as I

did, use ¼ " brass shelf supports for it to rest on.

If the shelf is removable, just remember to make it

about 1⁄8" narrower than the gap, so you can get it

in and out easily. The bottom shelf is made in a

similar way, with slats resting on cleats.

Finish up and make it roll

1. The entire cabinet is finished with a mix of 50

per cent boiled linseed oil and 50 per cent naphtha

or mineral spirits. (I prefer naphtha as it dries

faster.) Brush on a heavy coat, allow it to soak in

for 20–30 minutes, and wipe off any excess with a

lint-free cloth. Allow the finish to cure for 24

hours, then repeat. Because this is a penetrating

finish, repairing any scratches or general wear is

as easy as applying another coat, letting it soak

into the damaged area for a few minutes, and then

wiping off any excess.

2. The final step is to add casters. While they are

completely optional, they make it much easier to

move the island around the deck. Because your

barbecue island will be exposed to weather, solid

brass casters are a good choice. The ones I used are

small in diameter; if you plan to move your cart

around a lot, or your deck boards are quite uneven,

you may want larger ones. To attach a caster, drill

a ¼" hole in the bottom of each leg, then insert the

caster’s stem and secure with the supplied brass

screws.

Flip your island back over and roll it to its place

of honor on the deck. Load it up with your grilling

essentials and start planning dinner. You will

appreciate the extra space, and your barbecue’s side

shelves can now serve a more noble purpose: holding

a cold beverage while you attend to the steaks.

|

Free

BBQ Cart Wood Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|