The dictionary defines a bed as: An article of furniture to

sleep or rest on. From the beginning of the age of

enlightenment, man has gone well beyond this simple

definition. The bed has become the most glorious piece of

necessary household furniture in history. There have been so

many elaboration's of the same basic components that it

would make quite a list of designs. Every culture claims at

least one rendition of the "Bed" to be its own. Through the

years, I have had the extreme pleasure of building many

different bed concepts for both lodging establishments, and

individuals around the country. At some point along the way,

I decided to blend some of the best features of several bed

styles into one.

The English "poster bed" features four

tall corners that are either turned, tapered, or in some

cases, kept square. Sometimes in these beds the top is

resolved as a canopy that is held up by the four corners. On

the other hand, the provincial style bed features the use of

curves in the head and foot boards as well as in the

skirting. Both of these disciplines will often times

incorporate the use of draperies that make the sleeping

spaces very private. Where Provincial styled pieces are not

necessarily elegant, they do have style. The English

renditions are courtly by design, and offer a lot to choose

from when looking for features to elaborate upon for a new

design. My "elegant poster bed" borrows a little from both

of these styles, and at the same time has many amenities of

it's own. This bed is quite simple to build, and would be an

admirable addition to any home. I wanted to learn how to

build a bed that still had the Victorian look to it, but was

easy to build by the beginner. I think I have

succeeded in my mission.

The bed that was decided upon for the

purpose of this article was built for a standard queen sized

box spring and mattress, available at any store. The length

and width of the bed are a specific set of dimensions, but

the height, of course is optional. I decided upon 84" high

which works good in just about any room. Keep in mind that

the cutting list, and dimensions given in this article may

change according to the mattress size, and height that are

chosen. This bed was built of nominal size, (already

surfaced), 4/4 Alder which can be purchased by the board

ft., (random width and length), or pre-dimensioned at the

mill. Any specie can be substituted according to shop

capabilities, material availability, or personal taste.

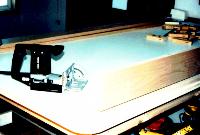

As with any building project we will

start with the foundation. The core of the sleeper base is

built as a rectangular plywood frame with ribs (figure 1). I

rip one plywood or composition 3/4" x 4' x 8' panel into six

strips that are 7 7/8" wide by 8' long. This formula allows

1/8" for each saw kerf which means there will be no remnants

or waste. This cutting procedure will yield enough material

to make a base that is 75 1/4" by 44 1/2". After this has

been built a three sided mitered layer of 3/4" finished

plywood is added onto the butt-jointed base to eliminate any

unsightly plywood edges, or screw heads. The dimensions of

the sleeper base will be 7 7/8" high x 46" wide x 76" long

when completed.. This fully assembled base will support the

plywood bottom panels, (two - 3/4" x 30 3/4"W x 87"L), and

leave 8" of overhang on the two long sides, and the front

(figure 2). Incidentally, the two remnants from the full

sheets used for the bottom panels can be cut down for the

outside finished plywood layer of the sleeper base.

Once the base has been completed,

focus can be turned to the four corner columns. These

columns serve as the structuring from which all else is

suspended. For these parts you should start with some

relatively flat, and straight pieces of 13/16" thick

material, (if nominally size hardwood is used). Cut four

pieces that are 5"W. x 83 1/4"L, and four pieces which are 5

13/16"W. x 83 1/4L.". These eight pieces will go together in

a butt-joint fashion (figure 3) to make the four corner

columns which will later be routed with a traditional shape

to minimize the glue seam.

Once the parts have been cut, they

should be laid out in order on the bench, and marked for

biscuit or dowel jointing (figure 4). The upper outside

edges of the columns will have a scrolled detail which

begins 5" down from the top. Because this shape is typical

on both sides of the individual columns, I usually will cut

the detail on one of the smaller parts, (before assembly),

and then use this piece as a template for the seven

remaining parts. This way I am assured that the detail will

be perfectly aligned on all four of the columns (figure 5).

A flat bench, or counter top serves as a good strong back

while gluing. Make sure that you use a framing square on the

inside while clamping (figure 6). To correct any tilting

that may occur, just adjust the individual clamp angle while

tightening that area of the post. If this is done while

working from one end to the other, the entire post will dry

square.

After the columns have been

fabricated, the indent notches can be cut into all four

corners of the plywood platform (figure 7). Note that this

is an area of the plywood which overhangs the sleeper base.

The corner columns start at the floor, and give an

independent support to the bed frame which is separate from

the sleeper base. Attached to the plywood edges with 2"

counter sunk screws, the columns are "tacked" in place while

the rest of the parts are being cut and fit (figure 8). The

screw heads in this area are ultimately covered by either

the bottom plinth blocks, or one of the bottom perimeter

trim pieces. On final installation a hardwood corner block

will be attached to the underside of the notched plywood

where it meets the columns.

In the next step, the upper skirt

boards are fit to the top of the corner columns. These four

perimeter boards have a many fold purpose. Primarily used to

square, and strengthen the top portion of the bed, they are

also a means of tying the posts together in an aesthetic

way. The skirt boards also serve to support the top canopy

frame. At the widest area of detail the skirt boards are all

6 3/4" wide. The scroll pattern is a little different

according to the two different lengths, but both patterns

begin at 5" wide on the ends. When designing a pattern of

your own, try using the same approach of drawing, and

cutting one quadrant, and using it as your template for the

rest of the parts.

After all four boards have been

scrolled, and edge sanded, (ready for routing), the ends can

be prepared for biscuit, or dowel jointing. At this point,

the two shorter skirts on the ends, or width of the bed, can

be permanently glued to the corner columns. The back of the

bed which will ultimately become the headboard, has the top

skirt board only to be glued into place. This can be done by

simply separating the two columns at the top, (which are

attached to the plywood base), just enough to fit the glued

board, and its biscuits or dowels. The front, or foot of the

bed, will have two "rails" to contend with (figure 9). The

bottom skirt, which is the same length as the top skirt, (50

3/4"), is cut 6 1/2" wide. Because this skirt rests on the

plywood bottom between the two columns, one of the columns

will have to be removed temporarily during the gluing

process. The idea here is that when all is said and done,

these assemblies at each end of the bed will become two

completed sections which can be removed for transporting,

and installation purposes.

With the two ends of the bed glued,

and in place, the top skirt boards can be fitted. These

boards will be approximately 75 1/2" long for this size

mattress, but it is a good idea to measure the distance at

the bottom between the posts just above the plywood, and

then cut the top skirts accordingly. These boards are not

glued into place because they must be removable for

transportation. While the clamps are holding the biscuited,

or doweled boards in place, a diagonal screw is driven in

each corner into the posts. The clamps can then be removed

without fear of the boards coming loose. Now the main

structure of the bed is complete.

At this point we move back to the

headboard end of the bed. Remember, this end has only the

top board glued in place, and is tacked to the plywood at

the bottom. A frame can now be built on the inside of the

columns which not only completes the structure, but is also

used to nail the headboard pieces (figure 11). The height of

this back panel is approximately 35" from the plywood deck.

About 20" of that will be covered by the mattress at the

bottom so it is a matter of opinion whether the finished

panel should continue all the way down to the top of the

plywood. I do run mine all of the way down. For this size

mattress width, you will need twelve pieces 5 1/16" wide to

complete the panel. For this bed I used a V-groove and bead

treatment where the boards come together on the edges. I

also used a simple pre-stained, loose spline system so you

will never see daylight if the boards expand, and contract.

I always lay the boards out on the bench first to achieve

the exact size that I need before they are installed (figure

12). Depending upon your equipment, or taste, you may elect

to use another type of headboard treatment such as a frame,

and beveled panel for your bed. I have made them many

different ways, and they all look good.

With the headboard complete, it is time

to focus on the top frame and crown skirt. The top frame is

made of four pieces that are 13/16 thick, and 5 3/4" W. This

formula allows for about 2 1/2" of overhang on the sides,

and front, and still leaves room to screw the frame down to

the top skirts and posts. For this size bed, the boards are

cut to 89 5/8"L, and 56"L. A simple butt joint with

biscuits, or dowels is used for this frame. Once the boards

are ready, the frame can be clamped and glued together right

on top of the bed (figure 13). This will save floor space

etc.

The crown skirt pieces which occurs

under the top frame is applied during the final

installation. This piece will run on the two sides and front

only. These pieces which are 13/16" X 2 1/4" wide should be

edge shaped with a shaper or router. They are then mitered

on the ends where the pieces meet, (figure 14), and kept

square in the back where the bed will go against the wall. I

attach this piece with screws from the back so that it can

be removed if the bed ever has to be relocated. You may

elect to use a different type of crown skirt, again

depending upon your capabilities, and taste. Remember the

piece is a mix of both French provincial, and English so

there is a lot of play in the area of design.

There are two side bottom retainer

boards which also go on during the final installation

(figure 15). I put a heavy bull nose on the edges of all

three retainer boards due to their precarious positioning.

The front retainer board, which is an important part of the

end frame, is already in place.

Now all that is left on our bed is the

garnishing. I like the use of boots, or plinths, (also shown

in figure 15), on all four corners of the bed. The headboard

section only requires plinths on each side, but the fronts

should have a two piece mitered plinth which encompasses the

whole corner. These blocks not only cover the screws which

hold the columns to the plywood bottom, but also serve to

protect the column where it meets the floor. All of the

plinths should be screwed on from the back so that they can

be easily removed. There is also a plywood edge on three

sides which has to be covered. For this I use a simple

molding which is 1/2" X 13/16". This piece can be made from

some of the downfall edges of the solid stock. A simple

traditional shape should be routed on both of the edges on

this piece.