|

Give your canoes and

kayaks some VIP treatment. Get them off the dock and

into a custom storage stand.

A couple of rickety old sawhorses. That’s what

passes for a winter storage system for my canoe. And

during canoe season, I just park it upside down on

the beach. I didn’t invest a lot in that canoe—in

fact, I don’t even like it much—so I don’t lose

sleep over UV deterioration, or weather damage to

the thwarts, or even a limb falling on it.

Certainly, a better model— the kind that many

cottage folks have— should be better protected. It’s

the owners of those boats who have been asking us to

feature a storage-system project for canoes and

kayaks.

The design and engineering challenges for this

project were many. We wanted it to store four

individual crafts, whether canoes, kayaks,

sailboards, or even rowing shells. It should be

stable on sloped cottage waterfront, as well as

provide the boats a basic measure of security and a

roof for some protection from sun, weather, and tree

debris.

Before you build, give some thought to the sizes of

boats in your flotilla: You can easily modify the

overall length of the rack or the position of the

cross-arms to suit. Though this is not a complex

project—a couple of weekends’ worth of work—you will

need a part-time helper to assemble it.

|

MATERIALS

All wood is cedar, except the roof boards,

which are pine. Substituting pressure

treated lumber for cedar, where possible,

will reduce the project cost significantly.

1 3/4x6

x 6' ridge

board support

1 1x6 x

16' roof

cap

11 1x10 x 16'

roof boards

6 2x4 x

8'

rafter brackets, trestle filler blocks,

ridge board supports, bridge pieces

4

2x4 x 10' trestle

header, brace studs, struts

8

2x6 x 10' lower

trestle frame, rafters

2

2x6 x 12' cross-arms

2

2x6 x 14' feet

3

2x6 x 16' upper

trestle frame, ridge board

2

4x4 x 8'

(length may vary according to terrain): legs

1 4x4 x

10' diagonal

braces

HARDWARE

8

3/8" x 4"

galvanized carriage bolts, nuts, and washers

10 3/8" x 8"

galvanized carriage bolts, nuts, and washers

500 #10 x 3!/2"

deck screws (beige)

500 #8 x 3"

deck screws (beige)

500 #8 x 2"

deck screws (beige)

4

#/8" x 10 1/2" turnbuckles

(hook-and-eye type)

4

#/16"

anchor shackles

12 5/16" x 4"

eyebolts, 12 nuts, and 24 washers

1

6'-8'

chain

4

#/16"

quick links

8

threaded eyes

4

hasps |

|

|

Leg assembly

1. Chances are your rack location isn’t level, so

your first step is to add extra height to the down

slope leg. Mark roughly where the two legs will go.

Sit a long, straight board on the ground, on edge:

one end at the upper leg mark, the other in line

with the lower mark. Lift the low end to level

(using a level, not an eyeball). Measure from the

ground to the bottom of the board at the low mark.

2. Cut the legs from the two 8'-long 4x4s —one 838"

long, the other that length plus the extra height

you just measured. Mark notches for the cross-arms

on the short leg and transfer the layout to the long

leg. The notches should be 15" deep by 55", but

check your 2x6s; their dimensions can vary. To cut

the notches, set your circular saw blade to cut 15"

deep, then make several passes to remove most of the

waste. Chisel out the rest and carefully smooth the

surfaces.

3. From two 14'- ong 2x6s, cut four 7' pieces for

the feet; with a jig saw, make the 15"-deep cut-outs

along the bottom.

Cut four 10" lengths of 4x4 for the filler blocks

(two from the leg off-cuts, two from the 10'-long

4x4). Drill a 5⁄16" hole through the middle of each

filler block for an eyebolt. Screw the feet to the

filler blocks with #10 x 35" screws and mitre the

top corners. In each filler block, install an

eyebolt and a nut (with a washer on each side of the

wood) and tighten. Slide each leg into the middle of

each foot assembly and clamp in place. Drill a 4"

hole through the foot assembly and the leg. Insert

an 8" carriage bolt, add a washer and nut, and hand

tighten.

Cross-arms and lower trestle frame

1. From the two pieces of 12'-long 2x6, cut four 6'

cross-arms. Each cross-arm has a curved bottom

taper—a detail that makes them look lighter and more

elegant. To mark smooth curves, all you need is a

thin, flexible strip of wood (a fishing rod works

too). Mark where you want the taper to begin and end

(leave the outside ends 35" wide). Holding the strip

against those marks, bend it to form a smooth curve.

If you don’t have a helper, a few finishing nails

will hold the strip in place while you mark. Cut and

sand the tapers and trim the top corners.

2. For the eyebolts in the cross-arms, you’ll need

to drill clearance holes, plus a countersink for the

nut. Drill a 1"-dia. hole 5" deep in the ends of

each cross arm and a 5⁄16" hole all the way through.

I had to cut about 5" off each eyebolt so it

wouldn’t protrude and scratch boats. If you put a

nut on the bolt before cutting, unscrewing the nut

will fix any threads that were damaged by your

hacksaw. 3. Square the cross-arms in the leg notches

and clamp in place. Drill two 4" holes in each;

install 4" x 4" galvanized carriage bolts, washers,

and nuts.

4. Miter the upper corners of the two 10'‑long 2x6s

for the lower trestle frame. A bit of juggling

follows. You and a helper must stand each leg

assembly (eyeballing that the leg is plumb) with the

bolt heads facing out, and clamp on one of the lower

trestle pieces. It must be tight to the lower

cross-arms and extend 6" beyond each leg. It will be

close to level because you already compensated for

the longer down slope leg, but minor shimming or

excavating may be needed to get it perfect. Plumb

the legs and screw on temporary braces. Screw the

lower trestle piece in place (positioning screws

where they won’t interfere with the bolts) so you

can remove the clamps. Add the other lower trestle

piece and bolt everything together with two 4" x 8"

carriage bolts per post; cut off the bolt ends and

file smooth.

Upper

trestle and ridge board

1. Trim three 16'-long 2x6s to 15'6" for the

upper trestle pieces and the ridge board.

Using two carriage bolts per leg, attach two

of these pieces as in the plans, 92" below

the tops of the legs. A 2x4 header

strengthens the upper trestle: Cut a

10'-long 2x4 to length (about 8'5") and

screw between the upper trestle pieces.

Screw a 2x4 trestle filler block—55"

long—between the upper trestle pieces, about

3" in from each end.

2. Mark the rafter positions on each side of

the ridge board: All (except the middle

rafter) are 24" on centre, starting in from

each end. Note that the top edge of each

rafter is 8" down from the top of the ridge

board. Centre the ridge board on top of the

legs and toenail in place. The ridge board

needs more support than just a few nails, so

I built a wood sandwich to hold it. The

“buns” are 2x4s, running along the legs from

the upper trestle frame to the top of the

rafters. The “lettuce and tomato” are made

of 5⁄4 deck board, filling the gap on either

side of the ridge board. Don’t forget to

match the rafter angle when you cut these

pieces. Screw the sandwich in place.

3. Mark the rafter bracket positions on

each upper trestle piece.

Bracing

1. The method I devised to give side-to-side

stability to the rack is pretty darned

clever! It adds rigidity to the structure

and adjusts for uneven ground. Attach each

turnbuckle (opened to about 8 of its total

length) to the lower cross-arm eyebolt,

using a 3⁄16" anchor shackle. Cut ieces of

chain to the distance between each

turnbuckle and the eyebolt below plus about

6". Fasten the chain to the eye with a 3⁄16"

quick link and hook the turnbuckle to the

chain. Check that the legs are still plumb.

Tighten each turnbuckle by hand only,

working each side a little at a time to

balance the tension. Remove the temporary

braces.

2. Cut the two 4x4 diagonal braces— 4' long

with 45° cuts at each end. I used a band saw

to cut decorative curves in the 4x4s, a

completely optional step. |

|

From a

10'-long 2x4, cut two 55"-long brace studs. Slide

them in place between the trestle frames and tap to

make an impression of the cross-arm nuts. Remove the

brace studs and drill 1"-dia. pockets, about 6"

deep. Clamp them back in place; they should sit

tight against the legs. Position the braces and mark

where they meet the brace studs. Remove both pieces

once more and screw the braces to the brace studs

with eight #10 x 35" screws. Then screw these

assemblies to the legs and lower trestle.

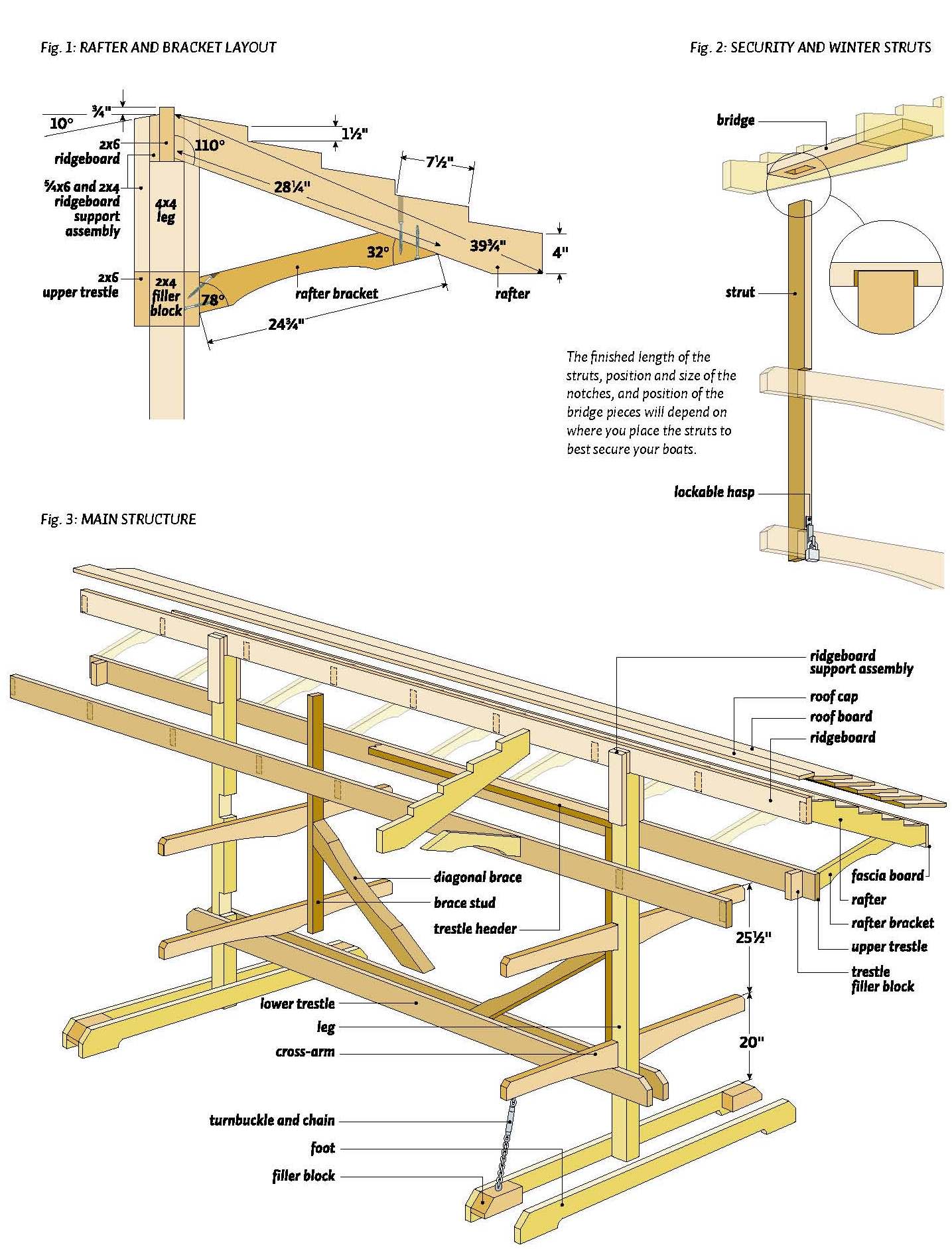

Rafters, rafter brackets, and roof

1. The rafters are cut from six 10' long 2x6s (three

per board), while the brackets are cut from four

8'-long 2x4s (lay these out carefully or you’ll need

more wood). While notching the rafters is

indeed tedious, it’s not just for style: The

louvered roof will reduce wind resistance.

Carefully mark and cut one rafter as a template for

the others (Fig 1). Mark where the rafter

brackets meet the bottoms of the rafters.

Mount the rafters on one side by screwing straight

through the face of the ridge board; secure the

other set by angling screws into them.

2. Before you start attaching the brackets

drill a clearance hole in each—about 3" in from the

end—to facilitate screwing to the rafters.

Secure the for end brackets to the for end rafters.

3. Rip the best 1x10 roof board down the center to

make two equal fascia boards. Trim to 15'6".

Mark the rafter positions on the top edge of each

fascia board. With your trusted assistant, attach

the fascia boards to the ends of the four bracketed

rafters using #8 x 2" screws; use a short

straightedge to drop the fascia just enough that the

roof boards will rest flush on top. Screw the

remaining rafters to the fascia and the ridge board,

and the rafter brackets to the rafters and the upper

trestle. I drilled a clearance hole down from the

top of each rafter for a second screw into the

bracket.

4. Trim the 1x10 roof boards and the 1x6 roof cap to

exactly 16'. Making sure the roof structure is more

or less square (it’s not a house, so don’t be a

perfectionist here), screw the boards on. Start with

the roof cap and work out from the peak. The roof

structure makes up a good 40 to 50 per cent of the

overall cost. If your canoe is like mine, accustomed

to neglect, you can omit the roof, but you should

still include the upper trestle pieces. They’ll only

need to be 10' long; lop off the top of the legs as

well, since you don’t need that height for the roof.

Security and winter-support struts

To handle snow load and provide a gesture of

security, my brother-in-law Tim and I came up with a

single solution for

both (see fig. 2). No, it won’t stop a determined

thief, but will prevent casual “borrowing” when

you’re not around.

1. Cut two 10' 2x4s to make four 5'-long struts.

With your boats on the rack, hold the struts against

the cross-arms, close to the boat hulls. Position

them so that removing your boats is impossible when

the struts are in place. Hold the top end of each

strut high enough that a bridge piece can secure it

(see Step 2, below), and mark notches in them to

mate with the cross-arms (the notches’ lengths will

vary). Cut the notches 15" deep.

2. Measure and cut a 2x4 to bridge the rafters over

each strut. Each bridge piece needs a pocket

cut into it to hold the top end of the strut. Clamp

struts to the cross-arms (plumb) and position the

bridge between the rafters. Mark where the

struts meet those pieces, then remove them and cut a

pocket (16" by 4" by 1"deep) for the struts. I used

a 16" Forstner bit, but a smaller auger bit and

chisel will work; likewise, you could use a router.

Screw the bridging pieces to the rafters (#10 x 35"

screws).

3. Attach a lockable hasp to the cross-arm and

strut as in the photo.

The little details

To hold the boats to the rack, we added threaded

eyes to the legs; bungee cords hooked into these and

the eyes at the ends of the cross-arms stop boats

from rattling around during a good nor'wester.

We screwed a few hooks to the upper trestle frame to

hang PFDs. You can also fashion a paddle rack to

hang your favorites—and the other ones you lend to

friends and relatives.

Finally, stain or paint the canoe rack if you

choose, but for my money, nature makes the best

finish job.

|

Free

Canoe Wood Boat Rack Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

|