|

Last summer, my wife,

Lynn, and I dropped in on cousin Kathleen and her

husband, Ross, at their Wahwashkesh Lake cottage.

After the customary welcome refreshments and sharing

of family news and gossip, Ross and I naturally

started talking cottage stuff. I noted that he had

recently replaced the deck on the side of the

cottage. This required closer observation, so we

abandoned the women and our lawn chairs and climbed

the steps for the requisite inspection. Ross said he

was considering installing a bench along the railing

side of the deck and wanted to know what I thought.

Since this bench/table project was already under

construction back at my place, I suggested it might

be a suitable alternative. Like stationary benches,

our bench/tables provide extra deck seating space,

but they can be moved around. The added bonus is

that they can also be quickly converted to half

picnic tables or combined to form a full one. This

eliminates the need for the traditional, but

cumbersome wood picnic table or a plastic or

aluminum patio set that always seems to take up too

much space. The multi-purpose benches are the hands

(and bottoms) down way to go.

|

|

FRAMING/LEGS

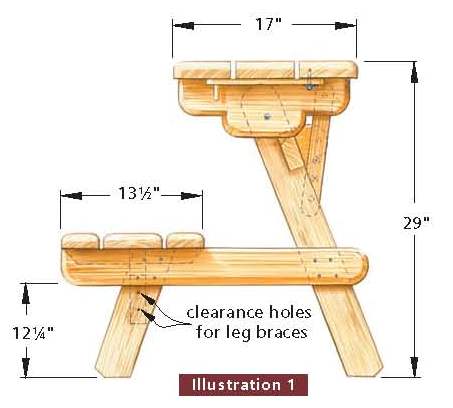

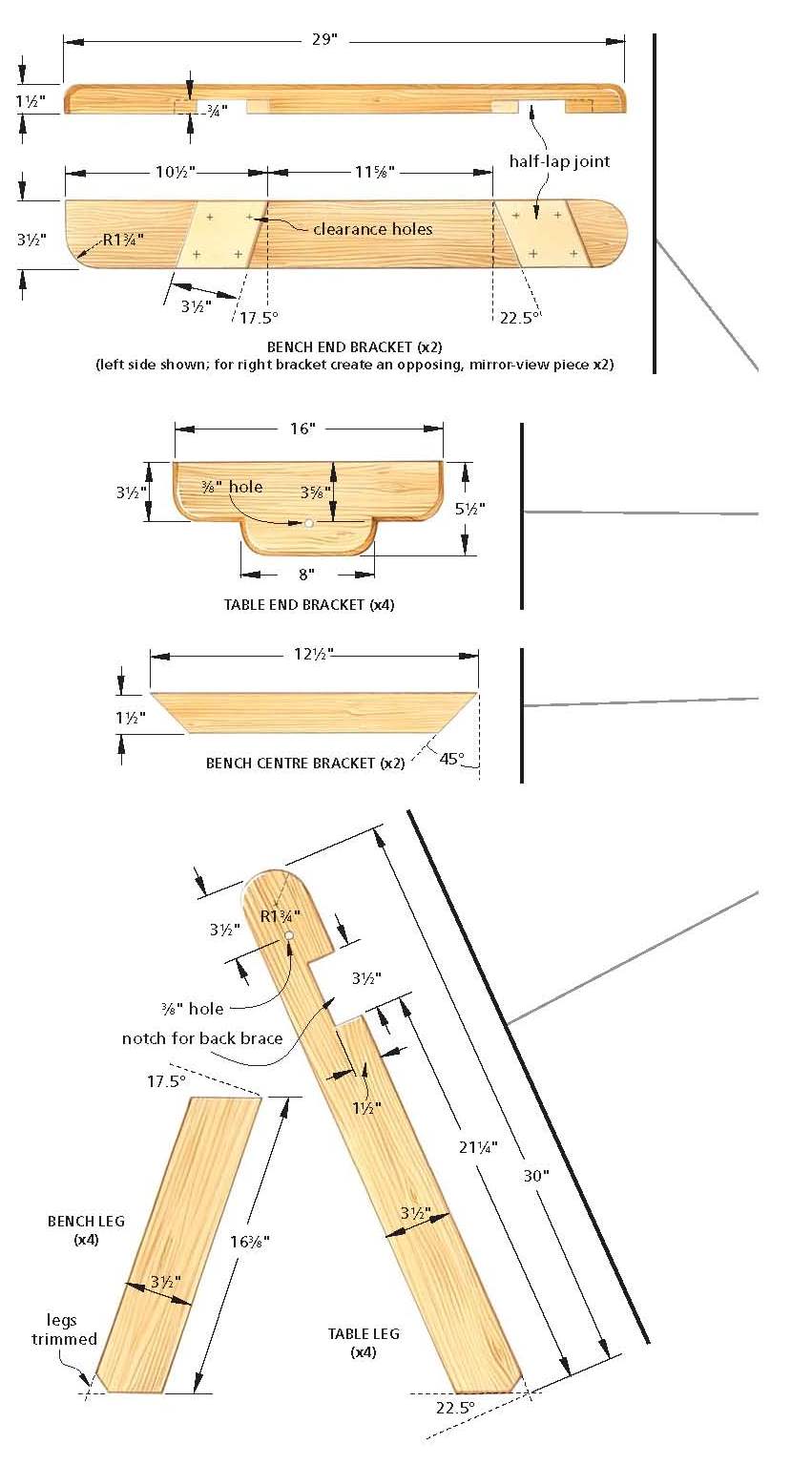

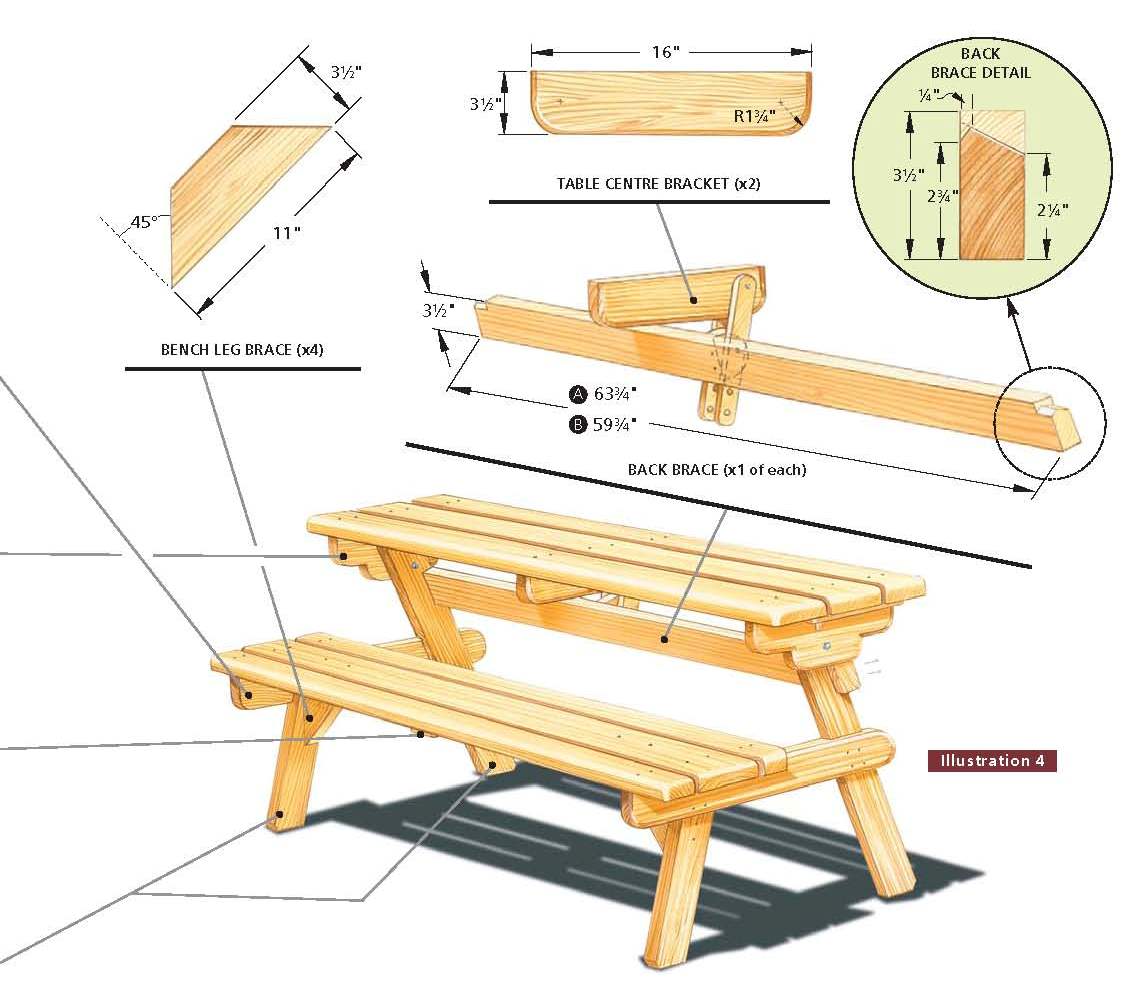

1. Refer to the Materials List and Illust. 4, to cut

out the main parts. If you do not have a really good

sabre/jig saw, or access to a band saw, you might

want to mitre the corners instead of cutting the

curves. It is virtually impossible to keep the blade

perpendicular with a standard sabre/jig saw in 11⁄2"

lumber so save yourself the aggravation.

2. The table legs require a 11⁄2" x 31⁄2" notch for

the back brace (Illust. 4). I accomplished this with

a dado blade on my radial arm saw. However, the same

can be achieved with a circular saw (or a handsaw,

for that matter) and a sharp chisel: Make several

passes 11⁄2" deep and then remove the remaining

material with the chisel. The bottom outside corners

of all four legs for each bench are trimmed to

reduce the possibility of splitting when the table

is tipped (Illust. 4). Drill a 3⁄8" hole, centred,

31⁄2" from the top of each table leg.

3. For this project, I opted to fashion 31⁄2"-wide

half-lap joints in the bench end brackets to

increase the frame’s rigidity and strength. Remember

to make two pairs of opposing brackets (Illust. 4).

Again, the circular saw and chisel method can be

used to make the notches if you don’t have something

better. Drill the eight clearance holes in each

bracket. I rummaged around in my rather sorry

collection of bits and found only a 9⁄64" – adequate

enough for #8 screws! For looks, you can router the

outside perimeter of each bracket (Illust. 3). I

like my trusty old 1⁄2" roundover bit because it

produces such a pleasing profile.

4. Sand the bench legs, table legs, and the bench

end brackets. Attach the legs to the bench end

brackets with #8 x 2" deck screws (the

brassy-looking kind) and Type II carpenter’s glue (Illust.

1). The advantage of Type II glue is its water

resistance. However, it runs more and tends to ooze

out of the joints longer than ordinary wood glue so

you’ll need to be extra careful when wiping it up.

5. Drill the 3⁄8" holes in the table end brackets

where shown (Illust. 4). Router the outside and

inside perimeters, except along the top edges, of

the four table end and two table centre brackets.

|

|

TABLETOP

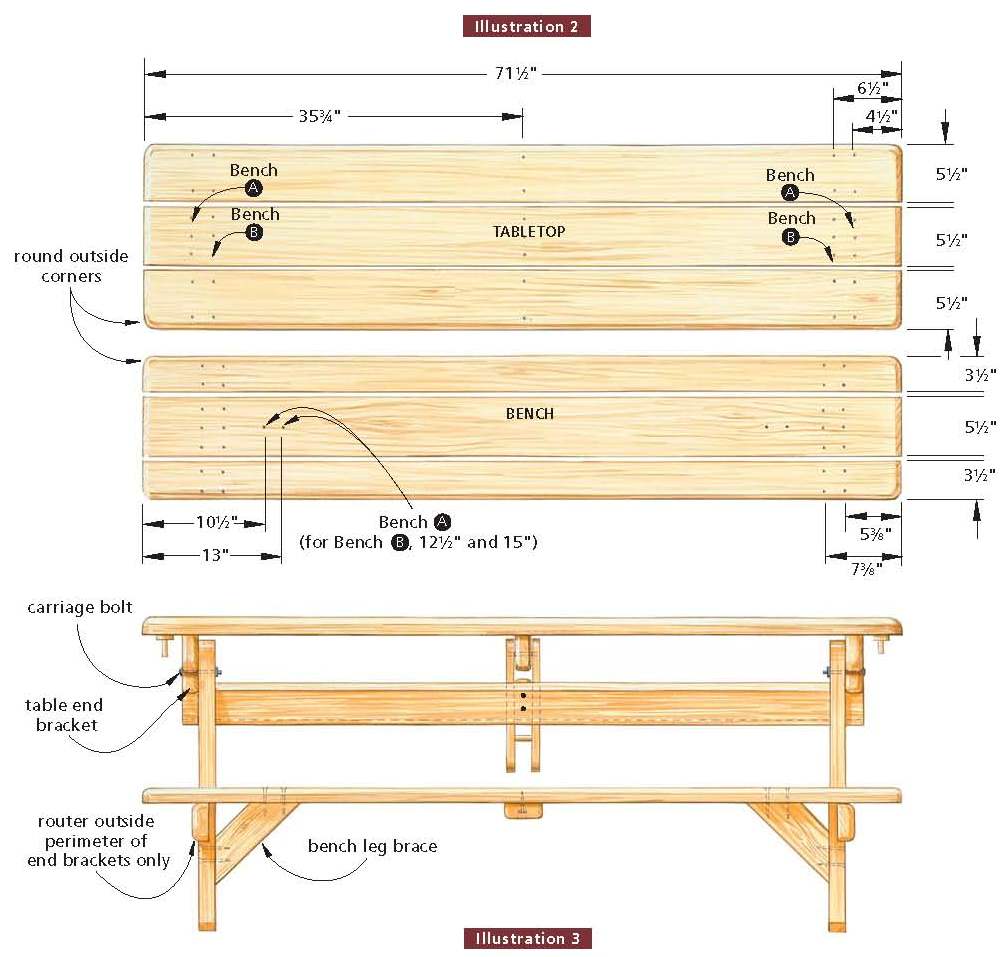

1. Select the six best 2" x 6" x 711⁄2" boards for

the tabletops. Round the outside corners of the four

outside boards as in Illust. 2. To enable the two

benches to fit together to form a large table, the

table legs must be offset (see photo). For Bench A,

the clearance holes for the table end bracket are

located 41⁄2" from the ends of the tabletop; for

Bench B, they are drilled 61⁄2" from the end. The

holes for the centre brackets do not need to be

offset (Illust. 2). Sand the table boards and the

six table brackets. Check for square, and screw the

boards to the brackets using #8 x 3" deck screws.

Leave about a 3⁄8" gap between each board to achieve

the 17" overall width for each table (Illust. 1).

2. Turn the assembled tabletop pieces upside down.

Attach the table leg assembly to the inside of the

table end brackets with 3⁄8" x 4" carriage bolts,

washers, and compression nuts. Make it a good snug

fit (no Herc, you don’t need to crush the cedar!).

Carefully stand the benches upright, and swing the

tabletop/bench backs up into the tabletop position.

|

|

BENCHES

1. Select the six bench boards (four 2" x 4" x

711⁄2" and two 2" x 6" x 711⁄2"). Round the outside

corners of the four 2" x 4"s.

2. Drill the clearance holes for the bench end

brackets in the bench boards. Again, because the

frames are offset, the clearance holes for Bench A

and Bench B are different (Illust. 2). While you’re

at it, drill the clearance holes for the bench leg

braces as well. Router the top perimeter of each

board before assembly. (I, naturally, made the

mistake of assembly first; I then had to remove the

innermost boards to router them.) Ensure that the

frames are square, and screw the boards to the bench

end brackets using #8 x 3" deck screws, leaving

about 1⁄2" between boards.

3. Router the outside edges of the bench centre

brackets and the leg braces before assembly. I

screwed the brackets in from underneath; countersink

the holes a good 1⁄2" because you will only be using

#8 x 2" deck screws. Drill the clearance holes in

the bench legs (Illust. 1) and attach the bench leg

braces to the centre bench boards and to the legs

with #8 x 3" deck screws. Sand.

BACK BRACES

The back braces (Illust. 4) measure 63-3⁄4" for

Bench A and 59-3⁄4" for Bench B. Each brace extends

about 11⁄2" beyond the table legs. Notches (see

inset detail) on the extensions act as stops for the

tabletops when they are tipped up, and the

extensions themselves stop the bench backs when

they’re tipped down. The measurements given for the

notches are starting points. Begin conservatively

and whittle away a bit at a time, checking for fit

as you go. I made the initial cuts with a backsaw,

but then I had to make several fittings, adjusting

the angles with a rasp and a very sharp chisel to

get them just right; be patient. Once you’re

satisfied, check for square, sand, then glue and

screw the braces to the table legs using two #8 x 3"

deck screws at each end.

|

Free

Picnic Table Wood Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

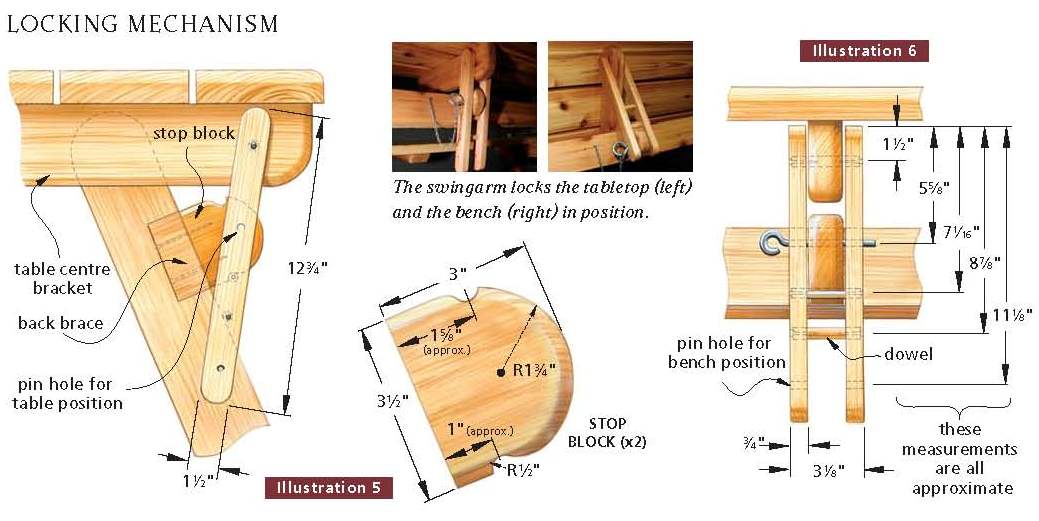

LOCKING MECHANISM

1. When the bench back is tilted down, it needs to

be secured; it must also be locked when it is in the

table position. Illust. 5 and 6 show details of the

locking mechanism that satisfies both requirements

(a eureka moment at five in the morning). The stop

block (Illust. 5) has been routered to match the

profile of the table centre bracket. Install it on

the back brace directly below the centre bracket

with glue and two #8 x 3" deck screws.

2. Make a 1⁄2" notch in the bottom of the stop block

with a round file or a surform tool. Taper the

leading edge of the notch to create a flat surface

that is roughly level with the tabletop. (The notch

on the top for the bench position is added later.)

3. The swingarm assemblies consist of 3⁄4" x 11⁄2" x

123⁄4" sides, rounded at the ends, and joined by

three 1⁄2" x 21⁄2" dowels, two on the bottom and one

on top. The dowels nest in 1⁄2" pockets drilled

7⁄16" deep (a forstner-type bit is ideal for this

job, as is a drill press). Drill a small clearance

hole through the centre of each pocket. This allows

excess glue to escape from the pocket during

assembly, and is the guide for the pilot holes that

you will need to drill for the #6 x 1" screws.

Temporarily assemble the swingarm by securing both

sides to the two bottom dowels only. Ours were

approximately 71⁄16" and 87⁄8" down from the top of

the arm.

4. With the bench back in the tabletop position

(clamped to hold it in place, if necessary),

position the swingarm so

that the top of the middle dowel you just installed

fits snugly into the notch you cut in the bottom of

the stop block (left- and photo, opposite). Then

slide the open upper end of the assembly over the

table centre bracket. Use a small nail or awl to

mark the position where the upper dowel will pass

through the table centre bracket (that little hole

you drilled will help. The position indicated in

Illust. 6 is approximate). Drill a 1⁄2" hole through

the table centre bracket (if you are using a drill

press, you will have to remove the bracket from the

table). Slide the top dowel piece through the hole

in the bracket, sanding the hole slightly, if

necessary, to get a nice fit.

|

Free

Picnic Table Wood Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

5.

Leaving the upper dowel in place, pull the swingarm

apart, sand, add glue to the pockets, and

reassemble. Screw the swingarm sides to the dowel

pieces with #6 x 1" screws. Use a rasp or surform to

adjust the fit of the middle dowel against the notch

in the bottom of each stop block (Illust. 6).

6. With the swingarm in place, drill a centred hole

through it and the stop block for the pin. (Precise

placement isn’t important: The pin is not

loadbearing; it functions simply to hold the

swingarm in place.) I made the pins from 3⁄8" x 8"

eye bolts. Cut the threaded portion off and taper

the ends with a flat file to remove sharp edges and

to make for a smoother fit. Though the threaded part

measures 3⁄8" in diameter, the smooth shank is

slightly smaller; start with a 21⁄64" hole. If that

is too tight, then move up to 11⁄32", and so on.

7. Pull the pin and slide the swingarm out. Tip the

tabletop into its bench position. Carefully cut a

new notch in the top of the stop block until the

bottom dowel can be seated securely (this will

prevent the bench back from moving). The notch must

be deep enough so that you can drill a second hole

through the bottom of the swingarms for the pin

(right-hand photo, opposite).

8. Run a 12" length of open-link light chain through

the eye of the pin, spread a link and hook it back

on itself, then close the link. Screw the other end

of the chain to the back brace with a #6 x 1" screw.

|

Free

Picnic Table Wood Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

|

9. Swing

the tabletop back up and lock it into position.

Router the outside perimeter only of the tabletops (Illust.

2). I free-handed this operation, trying to be

careful not to run into the gaps, but a cedar shim

or a piece of 3⁄8" scrap plywood wedged into the gap

– flush to the top and end – will prevent the router

bit from wandering into this space. Sand.

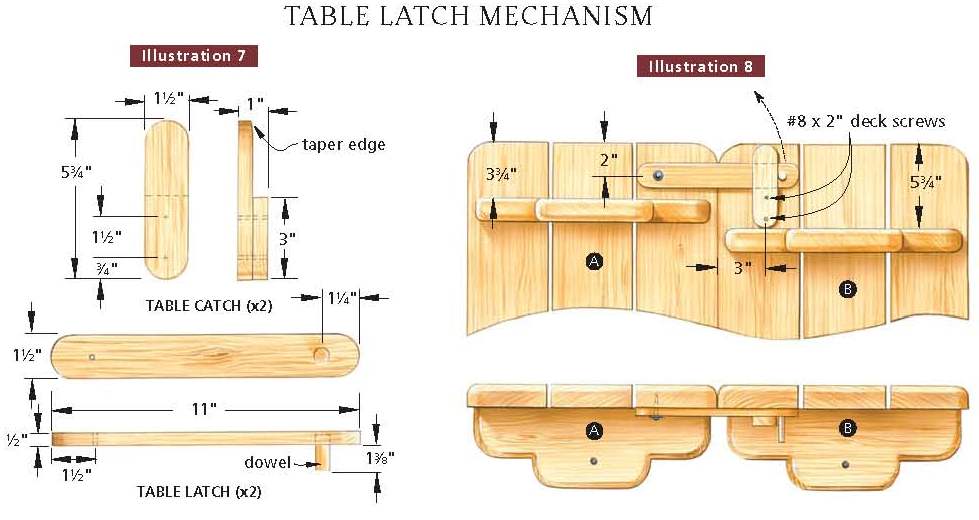

TABLE LATCHES

A simple latch ensures that when the benches are

combined to form a single picnic table, the tabletop

surfaces stay together (Illust. 7 and 8, above). It

is nowhere near as inspired as the tabletop lock,

but it works. Rip 1⁄2"-thick strips of 2" x 4" for

the latches and the catches. A 13⁄4" piece of dowel

is recessed into the swinging latch arm. The

illustrations show how these are assembled. Tack the

catches together with 1" finishing nails. Use a #12

x 11⁄2" screw for the latch because it will resist

turning. (Note that the two tables should be

separated before you move them.)

FINISH

I finished the tables with two coats of Varathane

Natural Oil Finish. This product provides protection

from the elements and preserves the cedar’s terrific

appearance. It is also really easy to apply – ain’t

that a bonus!

|

Materials List

(for 2 benches) |

|

Part |

Cutting List |

QTY |

Material |

|

Tabletop boards |

2" x 6" x

71-1⁄2" |

2 |

2" x 6" x 12'

(x2) |

|

Center bench

boards |

2" x 6" x

71-1⁄2" |

2 |

|

Tabletop boards |

2" x 6" x

71-1⁄2" |

4 |

2" x 6" x 8'

(x4) |

|

Table end

brackets |

2" x 6" x 16" |

4 |

|

Back brace –

Bench A |

2" x 4" x 63

3⁄4" |

1 |

2" x 4" x 14'

(x1) |

|

Back brace –

Bench B |

2" x 4" x 59

3⁄4" |

1 |

|

Table center

brackets |

2" x 4" x 16" |

2 |

|

Table legs |

2" x 4" x 30" |

4 |

2" x 4" x 10'

(x6) |

|

Outside bench

boards |

2" x 4" x

71-1⁄2" |

4 |

|

Bench legs |

2" x 4" x

16-3⁄8" |

4 |

|

Bench end

brackets |

2" x 4" x 29" |

4 |

|

Bench leg braces |

2" x 4" x 11" |

4 |

|

Bench centre

brackets |

2" x 4" x

12-1⁄2" |

2 |

|

Stop blocks |

2" x 3" x 4" |

2 |

|

Swingarms |

3⁄4" x 1-1⁄2" x

12-3⁄4" |

4 |

ripped from 2" x

4" offcuts |

|

Table latches |

1⁄2" x 1-1⁄2" x

11" |

2 |

|

Table catches |

1⁄2" x 11⁄2" x

83⁄4" |

2 |

|

*All lumber is

premium western red cedar |

|

Hardware |

|

Deck screws |

#8 x 2" |

1 lb |

|

|

Deck screws |

#8 x 3" |

1 lb |

|

|

Wood Screws |

#6 x 1" |

14 |

|

|

Wood screws and

washers |

#12 x 11⁄2" |

2 |

|

|

Eye bolts |

3⁄8" x 8" |

2 |

|

|

Finishing nails |

1" |

4 |

|

|

Carriage bolts

with washers |

3⁄8" x 4" |

4 |

|

|

and compression

nuts |

|

|

|

|

Light open-link

chain |

1' |

2 |

|

|

Hardwood dowel |

1⁄2" x 2' |

1 |

|

|

Varathane

Natural Oil Finish |

|

2L |

|

|

Type II

carpenter’s glue |

|

|

|

|