|

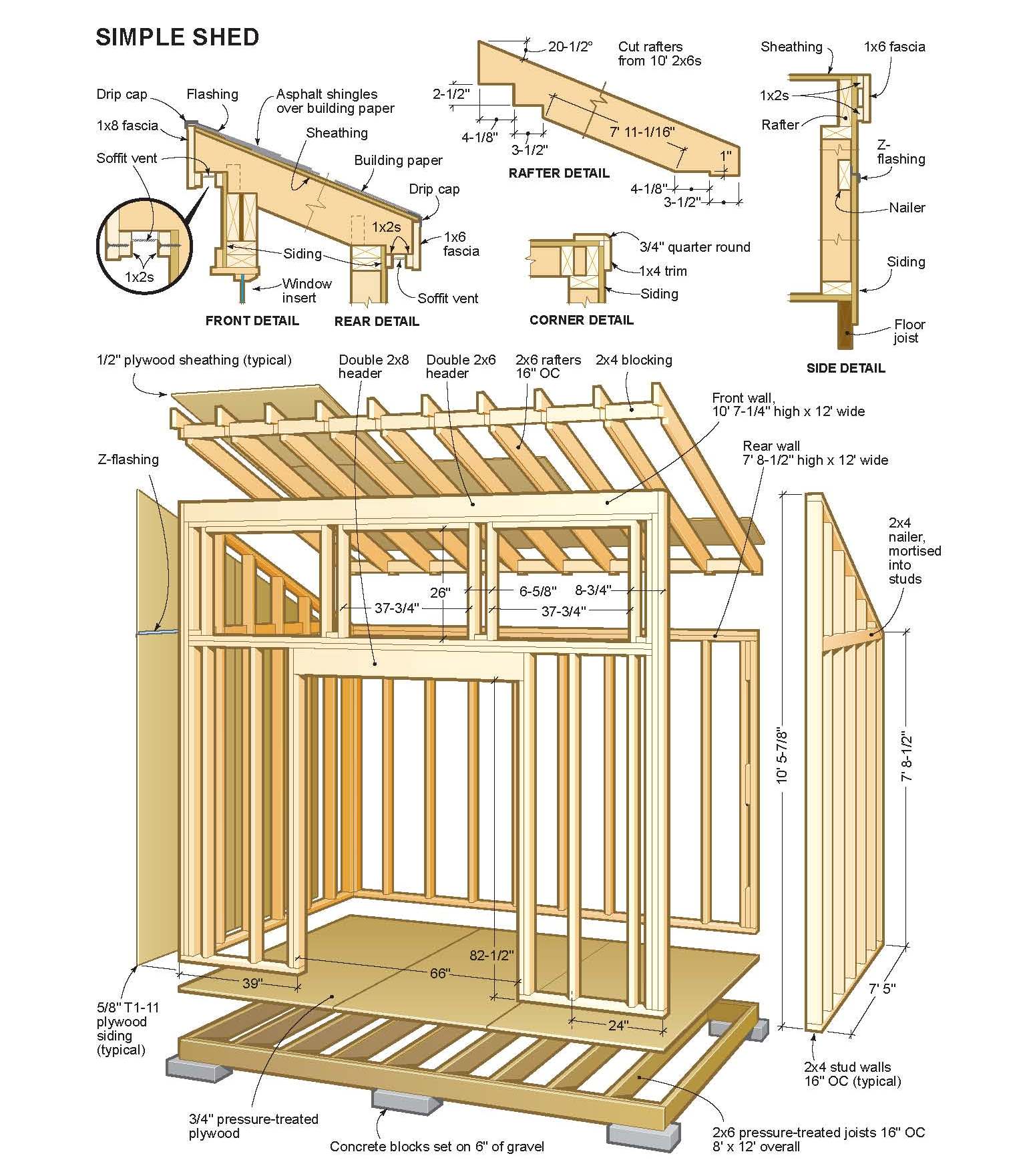

Keeping

yard-and-garden equipment clean, organized and

accessible makes lawn care less of a chore. But

finding adequate storage in your garage (if you’re

lucky enough to have one) can be a challenge. My

husband and I knew a shed was the solution, so we

created a custom design that serves our purposes. To

avoid the need for a building permit, we made the

shed relatively small: less than 100 sq. ft. (Always

check with your local code authority for building

requirements in your area.) Its appearance mirrors

the look of our rural contemporary saltbox house,

and the clerestory windows above the door let in

plenty of light while leaving adequate wall space

for shelving and hanging equipment. The construction

is straightforward; here are the basic steps.

|

Free

Simple Shed Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture)

Free

Simple Shed Plans

(Right Click on Image, and Select View as

Image or Save As to See the FULL SIZE

Picture) |

Foundation and floor

Start by laying out the perimeter. Drive 2x4 stakes

at each corner; then measure the layout diagonally

to ensure that it’s square. Dig 6-in.-deep holes for

8 x 12-in. concrete footing blocks. Fill the holes

with pea gravel, set the blocks in place and check

that they are level.

Use only pressure-treated lumber for the floor. Cut

the inside 2x6 headers 3 in. shorter than those on

the outside. Assemble the 2x6s so there is a

1-1/2-in. notch at each end of the header joist.

Mark the locations for the joist hangers 16 in. OC;

then install the hangers. Position the floor frame

on the foundation blocks and check that the assembly

is square and level. Cut the 2x6 joists and nail

them into the joist hangers. Fasten the 3/4-in.

pressure-treated plywood floor with 2-in. deck

screws.

Wall framing

You can use the shed floor as a surface on which to

build the walls before raising them into place. The

front wall is framed with 2x4 studs 16 in. OC and

has a double-2x6 window header and a double-2x8 door

header. Assemble the headers with 1/2-in. plywood

spacers. Cut a full-length sole plate (the door

opening is cut later), the top plates, the studs and

the window-cripple studs and blocking. To assemble

the front wall, nail the corner trimmers to the

corner studs. Mark the stud positions on the sole

plate and the first top plate. Working on the floor,

assemble the studs for the lower wall section.

Nail the second top plate to the first top plate;

then nail the end window cripples in place. Cut and

nail the short blocks to the top plate. Toenail the

cripple studs to the top plate with 8d nails; then

nail the 2x4 top plate to the cripple studs.

To install the top 2x6 header, nail up through the

plate with 10d nails and through the corner studs

with 16d nails. Nail the upper window blocking in

place.

Nail a long brace to the face of the front wall

diagonally to keep the wall square. Nail two short

2x4 blocks to the front of the floor to hold the

front wall in place and to keep it from slipping off

as you raise it. Fasten the sole plate to the floor

except along the door opening.

Refer to the drawing to lay out and assemble the

rear wall. Note that short blocks are used to form a

triple-2x4 end stud. Mark the stud positions on the

sole plate; then nail the studs in place. Fasten

both top plates.

As with the front and rear walls, cut and assemble

the side walls on the floor; then raise them into

position. Tack a 2x4 where the rear wall will be

placed, and build the side walls within the space

between the front wall and rear 2x4.

With a helper, raise the side walls into position

and clamp them to the front wall. Raise the rear

wall and clamp it to the side walls. Fasten the side

walls to the floor, the front wall and the rear

wall.

|

Prepare

the site; then build the floor frame and

position it on concrete blocks. Use only

pressure-treated lumber and galvanized

hangers and fasteners. |

|

Notch the side-wall studs for the 2x4 nailer.

Clamp the studs together; then cut

1-1/2-in.- deep kerfs. Remove the waste with

a hammer and chisel. |

|

Erect the side

walls and brace them with 2x4s. Nail 2x4

spacers to the floor to establish the rear

wall position. |

Framing the roof

Because the rafters overhang the siding on the back

wall, you’ll need to install the siding before you

begin framing the roof. We installed the

5/8-in.-thick T1-11 siding with 8d galvanized nails.

The back requires three 4x8 sheets, nailed evenly at

the top of the wall. All of the siding overhangs the

floor 3-1/2 in.

Mark and cut one 2x6 rafter (see drawing, front and

rear details) and check the fit. Cut the remaining

rafters and toenail them in place with 8d nails. Cut

and install the 2x4 blocking at the front and back.

Attach metal rafter anchors to the rafters and to

the walls.

Install the remainder of the siding. The sides take

two full sheets with the top edges centered on the

2x4 nailer. Nail Z- lashing on top of these sheets;

then cut the angled top side pieces to fit. Remember

to cut and remove the sole plate at the door

opening.

Cut siding to fit between the windows and install

Z-flashing on top of them; then install siding over

to the header over the windows. Now you can cut the

door opening. Save the scrap pieces to make the

door.

|

To ensure

consistent cuts on the rafter ends, use the

first rafter you cut as a template. |

Fascia, vents and roofing

Sheath the roof with 1/2-in. plywood and fasten it

to the rafters with 6d ring shank nails. Nail two

spacers to the top of the side; then add the 1x6

fascia (see drawing, side detail). Tack the soffit

vents to the bottom of the rafter overhang. Nail or

screw 1x2s to the top of the wall and against the

vent.

Nail the fascia board to the rafter ends and install

the second 1x2 vent support. Clamp it to the fascia

tightly against the vent; then fasten it in place.

Nail a drip cap to the rear roof edge; then apply

15-pound roofing felt (full width), starting along

the bottom edge. Use 2-in. top laps for the

successive sheets. Install the drip cap over the

felt along the side edges of the roof; then install

shingles. To seal the roof peak, use 8-in. metal

flashing bent over the fascia; then add a drip cap.

|

Shim the door

jamb with wood shingles when installing the

door.

A 2x4 ledger fastened to the shed’s floor

frame holds the back of the ramp. Rest the

front of the ramp on a 2x6 pressure treated

sleeper |

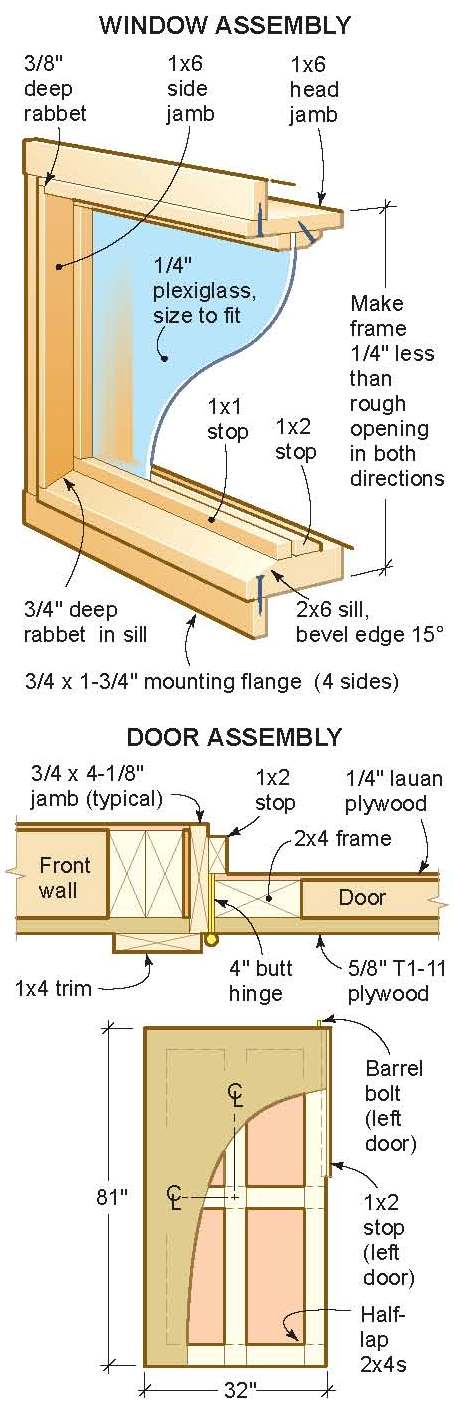

Windows

We made our own clerestory windows. The frames are

1/4 in. smaller than the rough openings. Cut the

jambs and sill to length. The sill has a 15-degree

bevel 2-3/4 in. along the front edge. Mark and cut

the 3/4-in.-deep rabbets at the sill ends for the

side jambs. Then cut 3/8-in.- deep rabbets in the

ends of the head jamb for the sides. Assemble the

frames with glue and nails. Cut 1x1 stops and nail

them in place. Install the mounting flanges; then

prime and paint.

We used 1/4-in. clear acrylic for the window

glazing. Bevel the back edges of the inside window

stops to make it easier to fasten them in place.

Prime and paint the stops; then insert the acrylic

and screw in the stops. Apply a bead of caulk along

the face of the siding and insert the windows; then

nail or screw the flanges to the framing.

Double doors

To build the doors, first rip the doorjambs from 1x6

stock. Cut 3/8 x 3/4-in. rabbets in the side jambs

for the top jamb. Nail the top jamb in place. Nail

stops 2-3/8 in. back from the front edge of the

jambs. Install 4-in. butt hinges on the side jambs.

Shim the door-frame assembly as required; then nail

it to the studs through the shims. Use a 4-ft. level

to keep the jambs plumb and flush with the face of

the siding. Nail the top jamb to the header through

the shims.

The double doors should have 1/4-in. clearance all

around. Make a door out of 2x4s laid flat and

half-lapped at the corners. Assemble the frame with

glue and 1-1/4-in. plywood on the front. Cut the

backs from 1/4-in. lauan plywood.

Install 1x4 door trim with a 1/8-in. reveal; then

hang the doors. Install a 1x2 stop along the inside

edge of the left door. Install a barrel bolt on the

left door and add a hasp on the outside.

Finishing touches

The ramp is framed with 2x4s and then covered with

2x4 decking attached with 3-in. deck screws.

Attach a 2x4 ledger to the floor header joist under

the door opening. Dig a 6-in.-deep area for the ramp

and fill it with pea gravel.

L-shape cane bolts are inserted into pipes on the

sides of the ramp to hold the doors open. We

installed 1x6 trim around the bottom of the shed to

protect the plywood siding from snow and added 1x4

corner boards with 3/4-in. quarter-round to finish

the corners.

Finally, we finished the shed’s exterior with

solid-color stain and white trim and primed and

painted the interior. The last step was to install

1/4- in. perforated hardboard and shelving to help

us make the most of our small yet sufficient

addition. |