|

|

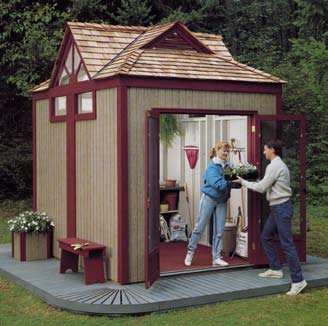

This storage shed will

provide you with two things at once: attractive

architectural lines to enhance your yard, and a

practical 80-square-foot work and storage space for

gardening and landscaping projects. Orient the

structure with the main window to the south, and the

workbench behind the window becomes the ideal place

to get a jump on the gardening season by starting

your plants in peat pots.

The shed itself is only 8 x 10 feet. Add the

wrap-around deck and it still only needs a space 16

x 14 feet; small enough to allow its gabled roofline

to grace all but the smallest of yards.

Customize the inside to suit your own requirements

for shelves, workbenches, and storage for tools or

toys. With a little imagination, you can also

convert the structure for other uses; you could make

it a playhouse, for example, or a poolside cabana.

It’s designed to be built in sections, so it can be

a one-person project with about a half-hour of help

from some friends.

We’ve made every effort to make these plans and

instructions easily understandable by an average

hobbyist in a home workshop. |

|

YOUR FREE SHED PLANS MATERIALS LIST |

| |

|

Structural Panels |

|

Quantity |

Description |

|

3 |

23/32-inch x 4-ft x 8-ft

Rated Sturd-I-Floor 24 oc (tongue & groove) for

floor and workbench |

|

9 |

5/8-inch x 4-ft x 8-ft

303 Siding (T1-11, 4-inch grooves) |

|

5 |

1/2-inch x 4-ft x 8-ft

Rated Sheathing (CDX or OSB) for roof |

|

1 |

5/8-inch x 4-ft x 8-ft

A–C plywood |

|

As Required |

Additional panels for

shelves |

| |

|

Lumber |

|

2 |

8-ft treated 2x4 |

|

7 |

10-ft treated 2x4 |

|

1 |

8-ft 2x6 for vent ends |

|

46 |

8-ft 2x4 |

|

4 |

10-ft 2x4 |

|

2 |

12-ft 2x4 |

|

4 |

8-ft 2x2 |

|

2 |

1-inch dowel, 4 ft |

|

7 |

1/2- x 2-1/2-inch trim,

8 ft |

|

1 |

2-inch shake molding, 8

ft |

|

2 |

8-ft 1x12 |

|

2 |

10-ft 1x6 |

|

2 |

12-ft 1x6 |

|

10 |

8-ft 1x4 |

|

26 |

8-ft 1x2 |

|

38 |

12-ft cedar 2x4 |

|

6 |

10-ft cedar 2x4 |

|

6 |

8-ft cedar 2x4 |

|

1 |

2-ft cedar 2x8 |

|

2 |

10-ft cedar 3/8- x

3-inch benderboards |

|

4 |

12-ft cedar 3/8- x

3-inch benderboards |

| |

|

Other

Materials |

| |

Gravel, concrete or

concrete blocks for foundation |

|

16 |

10-inch shelf brackets

(more for optional shelves) |

|

1 |

30-x 9-inch plastic

laminate for workbench top |

|

2 pair |

3-inch hinges |

|

2 |

2-inch knobs |

|

1 |

Screen, 30- x 36-inch |

|

1 |

Pre-hung window, 48- x

36-inch |

|

1 |

Pre-hung double screen

doors, 5-ft x 6-ft x 8-inch |

|

2 squares |

Roofing material |

|

2 |

1/8-inch acrylic

(Plexiglas) 30- x 60-inch for sunburst windows |

|

4 |

1/8-inch acrylic 12- x

24-inch for side windows |

|

8 |

2- x 12-inch framing

straps & nails |

|

As Required |

Nails and screws (16d

galv. box for framing; 8d galv. box for siding,

floor and trim; 6d galv. or bright box for roof

sheathing; 5d galv. finish for window stops; 16d

galv. finish for cedar decking). |

|

As Required |

Paint or stain (see

discussion). |

|

Overview:

The wood floor and walls can be built inside your

shop or garage and carried to the building site by

two people. The roof frame can also be carried,

though it is heavier. If you don’t have enough flat

floor space in your shop, the floor of the shed

makes a good surface to use for building the walls

and roof frame.

Remember that safety is more than slogans and signs.

Follow tool manufacturers’ recommendations, and use

caution and common sense around electricity and

cutting tools. The most important safety item in any

workshop is safety glasses; splinters that rate some

iodine and a Bandaid on your finger can cost you

your sight if they wind up in your eye.

Site Preparation:

Select and level the site for the gabled shed. A

leveled gravel foundation is the simplest, and is

recommended. Simply dig out 3 inches of soil,

replace with gravel, and level. Other options are a

concrete slab or concrete blocks.

If you live in an area where high winds are

possible, you will want to anchor the structure in

accordance with local procedures.

Floor and Wall Construction:

Construct the floor frame using treated 2x4 lumber.

Nail the floor panels over the frame. Ensure the

long dimension runs perpendicular to the joists. Do

not push the tongue-and-groove edges completely

together; leave a 1/8-inch space so the panels can

expand without causing buckling.

Study the framing guides for the walls, then build

the frames on a flat surface, such as the workshop

floor or the shed floor. Nail the siding on after

cutting out spaces for windows and doors. Be sure to

buy your pre-hung doors and windows before framing

and cutting out siding; if you find a bargain in

something slightly off-size, it’s easy to make

adjustments before building the wall section.

If the shed floor is to be used for building the

roof frame, set the walls aside for now. To erect

walls, set one side in place and temporarily brace

it with diagonal 2x4s. Nail to the floor with 16d

nails, angled so they penetrate the outboard joist.

Then set the back wall and side wall in place,

nailing to the floor and to each other. Set the

front wall in last, and nail to floor and sides.

Roof Construction:

The roof structure requires close attention, so go

slowly, read the plans carefully, and think about

how the sheathing is going to overlay the structure.

STEP 1. Construct the roof frame of

two 2x4s 121-1/2 inches, and four 2x4s 94 inches. Be

sure that no large knots occur where the frame,

valleys and rafters come together; you will have to

drive several nails close together, and it’s

important that the wood remain structurally sound.

The framing straps are typically bought flat.

Install them by nailing one side, then bend while

tapping with hammer for firm fit, and nail the other

side. Use strapping nails that do not penetrate all

the way through the lumber.

STEP 2. Install end rafters (A).

Place “fish mouth” lower ends in position, nail top,

then nail bottom to frame.

STEP 3. Nail main ridge (61 inches) between

two sets of end rafters. Note how the ridge is

positioned vertically, so that the top edge meets

the adjacent top edge.

STEP 4. Install gable end rafters (B) and

ridges (46-1/2-inch 2x4s).

STEP 5. Install valleys (C). At both ends,

the top side of the valley should

touch the top side of the ridges or rafters.

STEP 6. Attach 2x6 vent supports (47-1/2

inches) to end rafters.

STEP 7. Install hip ridge rafters (D). To

make compound miters, scribe line at 64 degrees and

set saw blade at 40 degrees. Four rafters are

required; two are mirror images of the other two.

Install each rafter with bottom end raised above

inside of frame, so that sheathing will lay flat on

rafter and outboard edge of frame. Install hip

rafters (E) the same way.

STEP 8. Install vent louvers. Make them of

1/2- x 2-1/4-inch lumber, or bullnose

molding for extra finished appearance. Cut ends at

45 degrees, which will give louvered angle. Nail

from back, starting at bottom. Staple screen from

behind. The frame may be installed now or wait until

installing other trim.

STEP 9. Measure, cut and fit roof sheathing,

but do not nail in place.

STEP 10. Gather three or more friends, half

of them with stepladders, and hoist the roof to the

top of the walls. Nail it in place and nail on the

sheathing. Finish the roof with flashing and

shingles or other roofing material. |

1. The walls are

fabricated separately, then

tipped into place and nailed.

2. Painting window trim before installation avoids

need to mask Plexiglas.

3. By doing most roof construction before hoisting

roof into place, you avoid lots of trips up and down

a stepladder. |

Doors, Windows, Shelves and Trim:

These may be installed in order of preference, with

one exception. If a window is selected with hardware

protruding into the interior, the shelf underneath

should be installed before the window. The

configuration of the shelf requires it to be

installed by placing one end in position

while holding the other end up, then sliding the

upper end down over the 2x4 stud. Protruding window

hardware would prevent that procedure.

To install the acrylic (Plexiglas) windows, first

build the frame of 1x2s behind the end rafters. Set

acrylic in caulking, then install outside frame of

1x2s on edge. Finally, install decorative sunburst

pattern. If trim is to be painted a different color

than siding, you may prefer to paint trim before

installing, especially around windows.

Deck Construction:

Build the deck of cedar, treated lumber

or other wood that weathers well.

For the straight sides, after the frame is

constructed, begin nailing deck pieces by nailing

end pieces in place, a quarter-inch back from the

end of the frame. Starting at one end, use a

5/8-inch block to position each deck piece, tacking

them in place. If the gap at the other end is too

large or small, go back and adjust other pieces

until the gap differences are not noticeable. Nail

the decking down with nonstaining finish nails.

For the corner pieces, build the 2x4 frame, then

mount the quarter-circle 2x8 a quarter-inch in from

the frame edges. Nail the two outside beveled

decking pieces first, leaving a quarter-inch at the

edge. Next measure to center and mount the center

decking piece. Then arrange the five pieces between

one side and the center so the gaps are even. Repeat

the process on the other side.

Install benderboards flush with the top of the

decking. For corners, use clear, straight-grain

wood, longer than needed. Nail one end, and bend

around, nailing as you go, then cut off excess. For

an extra finished appearance, round the outside

edges of the 2x4 decking with a belt sander to match

the benderboard radius.

Finishing Touch:

Use the siding left over from the window cutouts to

construct the planter box. Paint the plywood and

trim to match the colors of the shed. For details on

paint/stain selection, see the Building Hints later

in this article. |

|

|

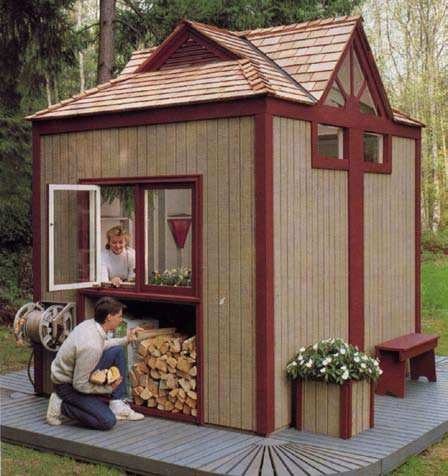

As

illustrated above and at right,

the storage under the window

is accessible from both sides.

Painting the interior a light

color, in combination with the

interesting roof geometry, gives

a feeling of spaciousness that

belies 8 x 10 dimension. |

|

This plan is continued on

page 2.....

If you like this free shed plan, you should check out the

ones we charge for!

Please make sure you check out our

shed

plans in our shed plans package before you leave our

site and see if they meet your needs!

|